SKYDEX ISOFIT: Enhance helmet comfort without compromising on protection

Military protection specialists SKYDEX have partnered with Helmet Comp to develop an innovative system that can be integrated into any tactical military helmet.

SKYDEX is a world-leader in advanced impact mitigation and energy absorption solutions. From armoured vehicles to bomb suits, helmets and body protection, SKYDEX is driven by the single purpose of ‘Protecting People and Things That Matter’.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

SKYDEX is a world-leader in advanced impact mitigation and energy absorption solutions. From armoured vehicles to bomb suits, helmets and body protection, SKYDEX is driven by the single purpose of ‘Protecting People and Things That Matter’.

We have extensive technical expertise and proprietary geometries, with advanced SKYDEX materials used to protect lives across a wide range of applications, such as vehicle protection, marine performance, sports protection, blast and ballistics, work wear/PPE, electronics, and more. With a passionate team of engineers and cutting-edge technologies, SKYDEX solutions outperform traditional materials.

For decades, SKYDEX has been trusted by armed forces to provide state-of-the-art protection in the harshest and most demanding conditions. Whether its enhancing comfort, shielding from impact, or lessening vibration-related fatigue, we work with our defence industry partners to enhance the protective capabilities of their products. Our patented, polymer-based geometries can be customised for each solution and meet your desired performance characteristics.

SKYDEX believes that optimal performance requires game-changing innovation. Our specialist team of engineers and product development professionals bring industry-leading knowledge and a collaborative approach to every project. Using our world-class on-site research and development facility, we validate solutions using an array of impact, pressure and vibration measurement tools.

With a process designed for speed, we design, prototype and test in a world-class testing capability. This, combined with our extensive investment in on-site manufacturing, have broadened our scope of products and speed to market.

With our rapid prototyping, production and global manufacturing network, SKYDEX can serve projects of any size and scope. Our supply chain flows through North America, giving our customers timely access to materials, while also reducing our carbon footprint. With a zero-waste model, we recycle excess material produced in the manufacturing process into our technology. SKYDEX’s energy efficient production standards ensure scalable manufacturing for global needs.

Minimising the effects of impact is the core of SKYDEX technology. We engineer solutions that offer superior impact absorption and remain durable in harsh environments, providing optimal protection that greatly reduces the likelihood of injury. Benefits range from multi-impact response and the ability to absorb more impact in less space, and SKYDEX offers enhanced performance that enables our partners to rethink the possibilities of their products.

Through the evolution of our technology, vibration attenuation has become a focus of our team as we understand the critical role it plays in a number of maritime, vehicle and other military sectors. With a growing awareness of the effects of whole-body vibration and the requirements to protect from the exposure to vibration, the EU Directive 2002/44/EC and other legislation has led SKYDEX to develop innovative and advanced solutions in the area of vibration attenuation.

Tuned to perform, SKYDEX geometries have also been integrated to improve cushioning through enhanced pressure distribution to enhance comfort of our users. With enhanced durability, the life-cycle of SKYDEX products greatly exceeds competitive materials and through the use of tough and durable materials, SKYDEX offers performance that you can trust over the extended usable life of our solutions.

SKYDEX provides optimal protection and performance across a broad range of industries. Whether it’s reducing vibration loads experienced in rough sea states, absorbing the extreme impact and shock delivered during unexpected explosions, or providing complete head and body protection within protective gear, SKYDEX can take on any challenge. From Major League Baseball stadiums to movie sets, construction sites and the military battlefield, we continue to push the limits of our technology.

Through ongoing research and investment in our technology, we are expanding our reach and establishing new partnerships, all with the goal of creating products that are engineered to protect and maximise performance.

Military protection specialists SKYDEX have partnered with Helmet Comp to develop an innovative system that can be integrated into any tactical military helmet.

SKYDEX has developed advanced technologies to combat noise, vibration, and harshness (NVH) during military operations, whether it occurs on land, at sea, or in the air.

SKYDEX, an industry-leader in advanced impact mitigation and energy absorption solutions, has developed a line of specialized blast protection products for armoured military vehicle platforms.

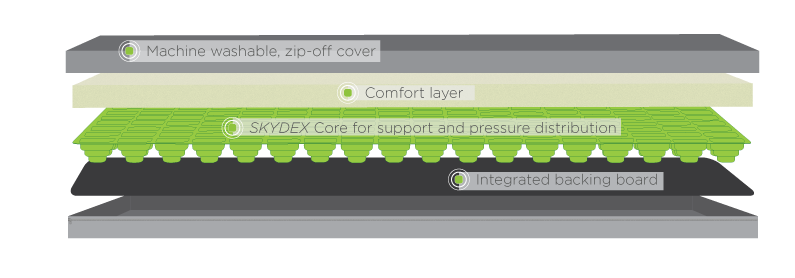

The SKYDEX Mattress features a modular design that outperforms and outlasts traditional mattresses. The proprietary SKYDEX Core Technology is a high-performance alternative to foam and inner springs currently used in mattress design. The SKYDEX Core has been specifically engineered to evenly distribute pressure and provide maximum comfort and support for the user.

IEDs and blast events targeted at armored vehicles have become a persistent threat for military forces worldwide, it has been estimated that 87% of injuries from IEDs are in lower extremities, particularly in the feet and tibia regions*. In response, vehicle manufactures strive to provide protective solutions that both increase survivability and ensure soldier operational readiness and battlefield effectiveness.

Blast seats are used in military operations to protect troops, commanders and drivers from the effects of sudden impacts, mines, and improvised explosive devices (IEDs). These seats are meant to not only serve as a cushioning layer to provide comfort for the vehicle occupant on rough, uneven roads, but are also a critical survivability component during a blast event.

The Stryker 8x8 wheeled combat vehicle family is based on the GDLS Canada LAV III 8×8 light armoured vehicle.

The Cougar Mine Resistant Ambush Protected (MRAP) vehicle is designed for deployment in urban and confined areas.

Oshkosh Heavy Expanded Mobility Tactical Truck (HEMTT) is an 8 x 8 diesel off-road tactical truck used by the US Army. Nicknamed Dragon Wagon, the HEMTT first went into service with the US Army in 1985, replacing the M520 Goer trucks.

Bushmaster MR6 (Multi Role 6) is an improved variant of the Bushmaster infantry mobility vehicle, which has been designed and manufactured by Thales Australia.

The PARS III 8x8 range of wheeled armoured combat vehicles is being produced by FNSS Savunma Sistemleri to meet the modern military operational requirements.

The mine-resistant ambush-protected (MRAP), all-terrain vehicle (M-ATV) Assault is a new member of the combat-proven M-ATV family of vehicles produced by Oshkosh Defense to meet the challenging requirements of the armed forces in hostile environments.

PARS 4x4 wheeled armoured vehicle, the latest member of the PARS family designed and manufactured by FNSS Defence Systems, was unveiled at the International Defense Industry Fair (IDEF) held in Istanbul, Turkey, in May 2015.

The new PARS 6x6 chemical, biological, radiological and nuclear (CBRN) reconnaissance vehicle from Turkish firm FNSS Savunma Sistemleri is based on the PARS 6x6 wheeled armoured combat vehicle platform.

The PARS is a new generation wheeled amphibious armoured combat vehicle being designed and manufactured by FNSS Savunm

Caiman is a high mobility, heavily armoured multi-theatre vehicle (MTV) designed and manufactured by BAE Systems to meet

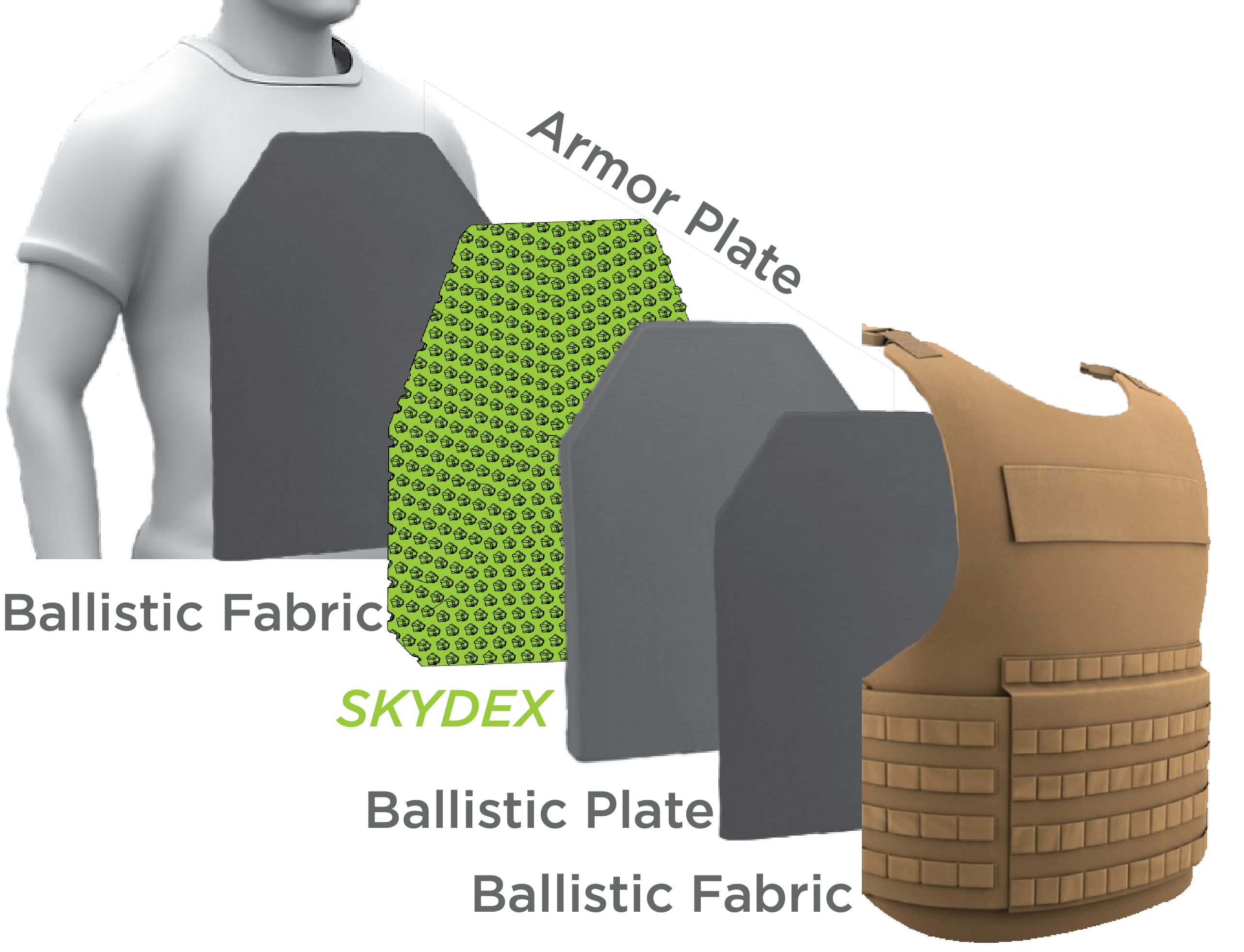

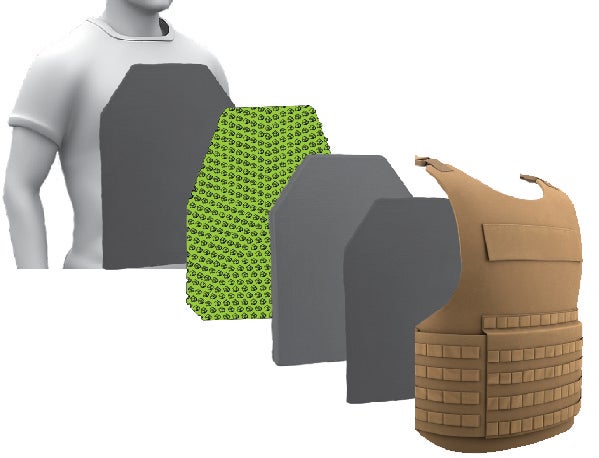

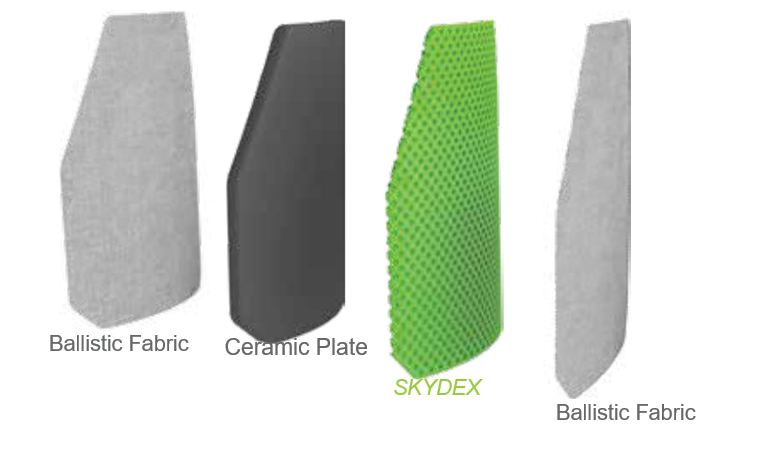

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has partnered with EDAG Engineering GmbH, TSS International BV and Avient Corporation, home to Dyneema®, to develop and prove performance through simulation of an advanced material to protect from behind armor blunt trauma (BABT) threat when wearing a bulletproof vest.

KYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has officially launched and began deliveries of the next generation in helmet protection, the SKYDEX IsoFit Helmet Protection System.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company will attend the Defense and Security Equipment International (DSEI) trade show in London on September 14-17, 2021.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has partnered with ArmorSource to enhance the company’s combat helmets with state-of-the-art technology and a new generation of protection with the SKYDEX IsoFit Helmet Protection System.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company has partnered with Helmet Comp to design the next generation of helmet protection and introduce the new, state-of-the-art SKYDEX IsoFit Helmet Protection System.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company will be participating in the Exhibitor Showcase at the Special Operations Forces Industry Conference (SOFIC).

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, has announced that it has partnered with TSS International, a world leader in vehicle protection solutions, to revolutionize how armored vehicle manufacturers are designing for blast protection.

In an effort to offer unrivalled comfort and meet the highest protection standards in the industry, Gecko enlisted SKYDEX to help with the development of their latest helmet, the Marine Ballistic Helmet (MBH).

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company is attending the ISPO Munich Online conference.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced that the company will serve as a sponsor at the International Armoured Vehicles (IAVs) 2021 virtual conference and will participate in the show for the sixth year in a row.

SKYDEX, a global leader in advanced impact mitigation and energy absorption solutions, today announced the recertification of its quality management system (QMS) to ISO 9001:2015.

IEDs and blast events targeted at armored vehicles have become a persistent threat for military forces worldwide, it has been estimated that 87% of injuries from IEDs are in lower extremities, particularly in the feet and tibia regions.

As boats travel through water at high speeds, they crest waves then slam back to the surface, sending shock through the hull of the boat into the occupants. Exposure to such forces can lead to discomfort, performance degradation, and injury. In a survey of Special Operations craft operators, 62% reported an injury they incurred on the water.

Blast seats are used in military operations to protect troops, commanders and drivers from the effects of sudden impacts, mines, and improvised explosive devices (IEDs). These seats are meant to not only serve as a cushioning layer to provide comfort for the vehicle occupant on rough, uneven roads, but are also a critical survivability component during a blast event.

The SKYDEX Mattress features a modular design that outperforms and outlasts traditional mattresses.

Watercraft operation introduces a range of dangers to both craft operators and passengers. Exposure to wave impacts, repetitive shock and whole-body vibration (WBV) has been linked to fatigue, decreased operational effectiveness and injury on the water.

Backface deformation (BFD) is how much a ballistic plate deforms into the user after it is hit by a projectile. The injury resulting from the deformation and the energy transmitted to the user upon impact is known as blunt trauma or backface signature.

Ceramic plates are a different style of ballistic protection than kevlar or other fibers in that instead of “catching” a bullet, ceramics actually break the bullet. Ceramic ballistic plates have been used for decades because of their ability to break a projectile shot at it and reduce the impact caused by the projectile.

The SKYDEX IsoFit® Helmet Protection System, integrates with most ballistic and bump helmets to provide unmatched helmet stabilization, a personalized fit and industry leading impact protection.