Hanwha Aerospace prepare to propose an offer to the US Government in which it would localise energetics production in a company owned and company operated model.

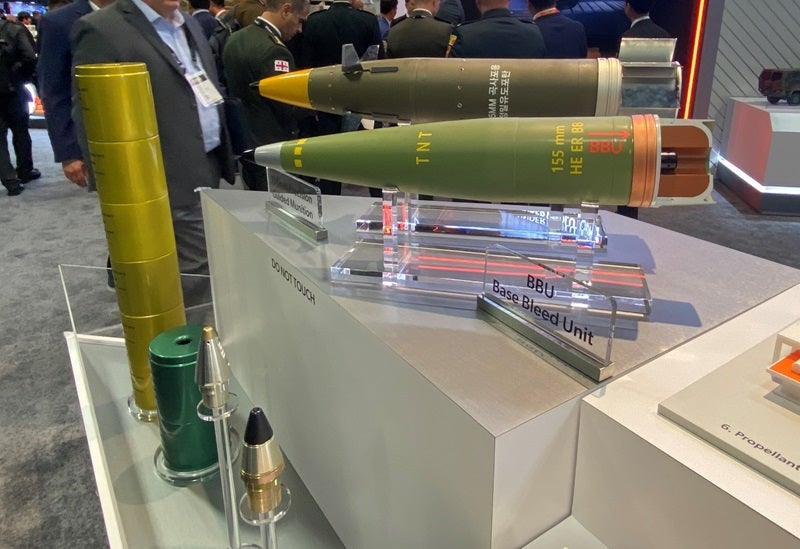

Broadly speaking, the energetics field include projectiles that rapidly release energy such as explosives, propellents, and pyrotechnics. But in Hanwha’s case, it intends to produce 155mm artillery rounds with base bleed units that extend the range of the shell in flight by ejecting gas at the base, thus reducing aerodynamic drag.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The US Army is shifting its focus from fighting insurgency missions in the Middle East to preparing for potential large-scale combat operations. In this backdrop, the artillery gap is severe considering the rate of consumption in a high intensity conflict zone like Ukraine, a beneficiary of up to 800 artillery systems of various calibres.

But it is not the first time that Hanwha has taken the brunt of a breathless American defence and technology industrial base.

The Korean group’s maritime arm, Hanwha Ocean, is helping to restore US shipbuilding as its yard in Geoje becomes an maintenance, repair, and overhaul site for US Navy supply ships as well as the company’s acquisition of Philly Shipyard.

Production challenge

To this end, the US Department of War (Department of Defense) is increasing production from 168,000 to 1.2m rounds per year, according to a Government Accountability Office report from July 2025. To help support this increase, the Army is qualifying additional suppliers for metal shells and metal forging capabilities.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIn fact, the US Government reprioritised funds earmarked for Ukraine toward the extraction of tungsten, a metal alloy that is used for various defence products, including shells because of its high density and hardness which helps to penetrate hardened targets.

Fully Automated Modular Charge Facility

As the challenge to produce rounds persists, Hanwha is offering to invest in the construction of a Fully Automated Modular Charge Facility in the US.

A Hanwha spokesperson told Army Technology that rounds will be produced completely autonomously – not a single person inside the factory.

While the group is in discussions with the US Government to establish such a facility, the first Fully Automated Modular Charge Facility will open in South Korea in 2027. It is said that Hanwha may also approach the UK and Europe next too.

At full capacity, Hanwha Aerospace anticipate the production of 300,000 rounds per year.