Global drive to make steel production greener and more efficient

Steelmakers are aiming to change their production processes to use renewable energy sources and sustainable raw materials.

Armox has been designed by SSAB to provide harder and tougher steel to manufacturers of protection equipment.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Armox® is a well-known high-end protection plate designed by SSAB to provide manufacturers of protection equipment with harder and tougher armour steel.

The Armox® brand is one of many steel grades from SSAB, a Swedish company specialising in quenched and tempered steels for protection, wear, structural and tooling applications.

Armox® is delivered in a quenched and tempered condition, ready for processing and installation.

The standard Armox® grades are manufactured with a Brinell hardness from 300HBV to 600HBW and beyond. These grades have guaranteed mechanical properties for hardness, tensile strength and impact toughness. The plates range in thickness from 3mm to 150mm, depending on the selected grade.

SSAB also offers an ultra-high hardness ballistic grade, Armox® Advance. It has a guaranteed Rockwell C hardness of 58HRC to 63HRC. This grade comes in thicknesses from 4mm to 7.9mm and is intended for add-on armour applications.

Armox® provides ultimate protection in combination with ease of use in the workshop thanks to the steel’s relatively high toughness. Armox® grades are classified with protection levels according to several militaries and other standards for armour steel. They have been used to improve safety for people and property in the world’s most dangerous environments for more than 40 years. Armox® has quite literally been tested in the field.

SSAB also offers Ramor® protection steel, which is a direct-hardened steel with guaranteed hardness, good workshop properties, and excellent surface properties. It is primarily intended for civilian applications. Ramor® is produced in 300HBW to 600HBW hardness and is available as cut-to-length sheets or heavy plates in thicknesses from 2.2mm to 30mm, depending on the actual grade’s hardness.

Protection engineers and OEMs manufacturing protected vehicles or other vulnerable targets can tailor their designs by utilizing the wide portfolio of grades and dimensions for Armox® and Ramor®.

In addition to systematic quality checks at its own laboratories, SSAB collaborates with independent and internationally accredited centers for carrying out various ballistic tests. At SSAB, the entire production process is built to ensure all steel products leaving the factory match and exceed the international standards, conforming to customer specifications.

SSAB is in the process of phasing out its traditional steelmaking processes in favour of fossil-free technologies. This transformation applies to all SSAB steels, Armox® and Ramor® included. SSAB is already producing steel from two different sustainability concepts. One is based on HYBRIT technology, making SSAB Fossil-free™ steel with green hydrogen instead of coal and cok. The other concept, SSAB Zero™, is based on recycled steel produced with fossil-free energy.

Steelmakers are aiming to change their production processes to use renewable energy sources and sustainable raw materials.

The metal has been around for decades used to make heavy industry products. It has since gained traction as a commercial and domestic construction material and for artistic projects.

It is a well-known fact that steel is one of the most sustainable materials in the world. Indestructible, recyclable and reusable, it keeps returning value in every incarnation

When planning for a new product where steel is to be the main component, you must first decide on its…

It goes without saying. If you are the supplier of a steel plate that could be the only thing standing between a human being, and a bullet travelling at the speed of 925 metres/second - you better be on the safe side.

No other steel manufacturer in the world has the same knowledge and expertise in terms of armour steel production as SSAB.

SSAB’s protection plates have a lean chemical composition which supports a high degree of weldability.

SSAB and Italian crane manufacturer Fassi have reached an agreement for future deliveries of steel produced with virtually zero fossil carbon emissions.

SSAB has received the necessary permit from the Land and Environmental Court in Umeå to build and operate a mini-mill in Luleå, Sweden, that will replace the current steel plant.

SSAB and Smith Stål from Norway have signed a letter of intent involving future deliveries of fossil-free steel. Together they are building a strong value chain for their Norwegian customers.

SSAB and Framery have announced a strategic collaboration to integrate fossil-free steel into the production of office pods, marking a significant milestone in sustainability within the workspace sector.

SSAB and Meka Pro Oy have agreed on deliveries of fossil-free steel that will be used to manufacture cable management systems, such as cable ladders and cable trays.

SSAB has reached an agreement with Trelleborg Sealing Solutions Kalmar AB to deliver fossil-free steel to be used in anti-squeal plates, so-called shims for brake pads.

The HYBRIT initiative now presents the results of six years of research in a final report to the Swedish Energy Agency. The report shows that direct reduced iron produced with the HYBRIT process has superior characteristics compared to iron produced with fossil fuels.

Wibe Group and SSAB have reached an agreement on deliveries of fossil-free steel to be used in Wibe Group’s cable management systems, such as cable ladders and cable trays.

SSAB and Firth Steels have entered a long-term partnership for the supply of steel made with virtually zero fossil carbon emissions. The partnership will help Firth Steels reach its goal to further improve sustainability and reduce the CO2 footprint of their products.

SSAB representatives will participate in more than 20 seminars and round tables during the United Nations Climate Change Conference, COP28, in Dubai.

SSAB and Sandvik Mining and Rock Solutions have signed a letter of intent to secure fossil-free steel for use initially in the production of Sandvik’s loaders and trucks.

Steel company SSAB and wave energy developer CorPower Ocean have signed an agreement to explore the development of one of the world’s first wave energy power plants made using fossil-free steel.

Epiroc becomes the first company in the mining industry to sign a delivery agreement with Swedish steelmaker SSAB for SSAB Zero™ – a fossil carbon emission-free recycled steel produced using fossil-free energy sources.

SSAB is taking part in meetings and seminars in conjunction with the United Nations Climate Change Conference, COP27, which this year is hosted by Egypt. SSAB will, as part of Business Sweden’s delegation, raise the need for enabling regulatory frameworks and a level playing field, as well as highlight the importance of partnerships and cross-sector co-operation to reach Paris Agreement targets.

SSAB has entered an agreement with U.S.-based Shape Corp., a tier-one automotive supplier of lightweight body structures, to deliver fossil-free steel crash management and body structure systems to market.

SSAB, LKAB and Vattenfall are inaugurating HYBRIT’s pilot facility for fossil-free hydrogen gas storage at Svartöberget in Luleå, Sweden. The rock cavern storage facility is the first of its kind in the world. The inauguration ceremony marks the start of the two-year test period, which will run until 2024.

SSAB starts a partnership with Epiroc, a leader within mining and infrastructure industry supplies, on fossil-free steel that Epiroc plans to use in its mining equipment production.

SSAB and Swedish electric car company Polestar have signed a letter of intent to start strategic collaboration to create a climate-neutral car.

SSAB will display its plan for fossil-free steelmaking at Expo 2020 in Dubai, as well as highlight the importance of fossil-free value chains as a solution to the climate crisis. A green transition is necessary to tackle climate change, it is also the best business plan, strengthens competitiveness and builds prosperity.

SSAB is to deliver fossil-free steel to Cargotec, a leading provider of cargo and load handling solutions. Cargotec plans to use the fossil-free steel in their cargo handling equipment.

SSAB is teaming up with Faurecia to jointly explore the development of fossil-free advanced high-strength steel for use in the automotive seating business.

SSAB is now issuing an invitation to participate when the world’s first fossil-free steel is ready for delivery to the customer, a milestone on the road to a completely fossil-free value chain for iron and steelmaking.

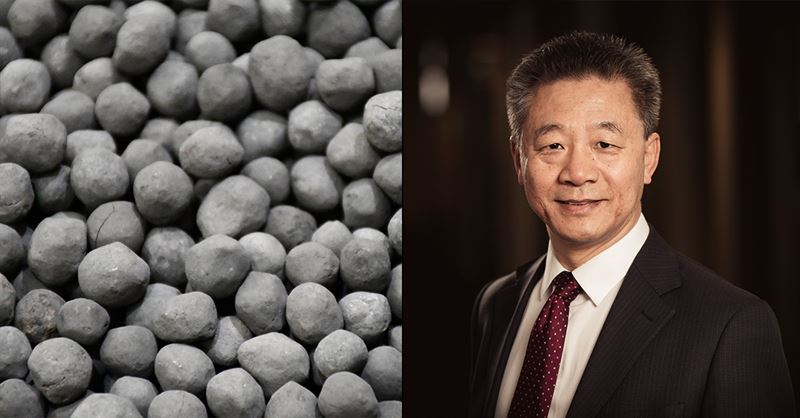

SSAB, LKAB and Vattenfall have now produced the world’s first hydrogen-reduced sponge iron at a pilot scale. The technological breakthrough in the HYBRIT initiative captures around 90% of emissions in conjunction with steelmaking and is a decisive step on the road to fossil-free steel.

Three new products have now been added to the Duroxite range of overlay solutions from SSAB: Duroxit AP ELECTRODE, Duroxite AP WIRE and Duroxite CR-ZERO WIRE.

SSAB’s earnings improved sharply during the first quarter of 2021. Demand is strong, prices are increasing and we have taken strategic steps in our transition to a fossil-free steel production. The recovery that started during autumn last year has strengthened during the first quarter.

Volvo Group and SSAB have signed a collaboration agreement on research, development, serial production and commercialization of the world’s first vehicles to be made of fossil-free steel. Volvo plans already this year to start the production of concept vehicles and components from steel made by SSAB using hydrogen.

SSAB, LKAB and Vattenfall are now taking a new, decisive leap forward in their work to make fossil-free steel for the global market. Industrialization of the technology being developed through HYBRIT will start in Gällivare, northern Sweden, where the world’s first production plant for fossil-free sponge iron – from feedstock to steel – is being planned.

Karl-Petter Thorwaldsson, former president of the Swedish Trade Union Confederation, LO, is to join SSAB as Senior Advisor to strengthen the company’s government relations and public affairs in Sweden and at the EU level.

The year 2020 was affected by a weak market as a consequence of Covid-19, and SSAB’s operating result fell to SEK -325 (2,159) million. The market picked up during the autumn and SSAB’s shipments and capacity utilization improved. This lifted earnings for the fourth quarter of 2020 to SEK 557 (-1,131) million.

SSAB confirms that it is in discussions with Tata Steel Group concerning a potential acquisition of Tata Steel Europe’s IJmuiden steel mill and related downstream assets.

SSAB invites you to a presentation of the quarterly report at 9.30am CEST on Thursday October 22, 2020. The briefing will take place by conference call that will also be webcast on SSAB’s website. The report is scheduled for publication at 7.30am CEST on the same date.

SSAB, LKAB and Vattenfall will be starting the test operation of HYBRIT’s globally unique pilot plant for the production of fossil-free sponge iron, a decisive step toward fossil-free steel production, on Monday, August 31 in Luleå.

SSAB’s operating result for the second quarter of 2020 was SEK -251 million, down SEK 1,567 million compared with the second quarter of 2019. The steel markets were affected by lower economic activity following the outbreak of Covid-19.

SSAB’s operating profit for the first quarter of 2020 was SEK 343 million, down SEK 1,331 million compared with the first quarter of 2019. The first quarter of last year was characterized by more favorable market conditions, especially for SSAB Americas.

SSAB invites you to a presentation of the quarterly report at 9.30am CEST on Monday April 27, 2020.

Prime Minister Stefan Löfven breaks the ground for a globally unique pilot plant for HYBRIT, the initiative from SSAB, LKAB and Vattenfall for fossil-free steel. The three owner companies, with the support of the Swedish Energy Agency, recently decided to join forces to invest Skr1.4bn in the pilot plants, one of which will be built at SSAB’s site in Luleå. This means that SSAB is taking the next important step towards the goal of being totally fossil-free by 2045.

SSAB, LKAB and Vattenfall cordially invite the media to a joint press conference to be held on Monday April 4, 2016 starting at 10am CET to announce a joint project that can play an important role in a future fossil-free Sweden.

SSAB has announced it will be showcasing its latest product offerings at this year's International Defence Exhibition & Conference (IDEX).

The Armox 370T Class 1 is a rolled homogeneous armour for vehicles.

The Armox® 370T Class 2 is a rolled homogeneous armour (RHA) that combines excellent shock resistance and toughness.

The Armox® 440T is a blast protection plate that combines excellent penetration and shock resistance.

The Armox® 500T is a high-hardness armour with extrordinary toughness properties.

The Armox® 600T is an extra-high-hardness armour with very good resistance against penetration. The 600T is used as an add-on protection plate or where weight is critical.