Soucy Defense (Soucy) specialises in advanced composite rubber track (CRT) technology for 45m vehicles.

Soucy Defense (Soucy) specialises in advanced composite rubber track (CRT) technology for 45m vehicles.

This technology is supported by functional analysis design, its own rubber compounding and research and development (R&D) facilities, advanced rubber compound characterisation, modern dynamic simulations, customised production equipment and an automated bench test.

Rubber tracks offer high durability and performance, as well as low lifecycle costs for tracked vehicles, and can be adapted to suit any specific requirement. This ductile composite rubber track technology can be customised to meet a wide range of requirements using advanced rubber compounding and computer simulations.

Rubber track advantages for tracked vehicles

Rubber tracks have many advantages over traditional steel tracks.

The first is weight reduction. Typically, this represents roughly half of the steel track weight. For example, a 39t CV90 vehicle saves nearly 1.3t by replacing the T157I steel track with Soucy’s rubber track. For vehicles subjected to weight limitations such as the mobile protected firepower (MPF), the rubber track is an alternative solution.

Rubber tracks also reduce the vibration level by up to 70%. This reduces crew fatigue, wear and tear on electronics, and ammunition insensitivity. They also decrease noise levels up to 13dB, which improves crew health and safety, as well as mechanical condition awareness. Communications become more efficient and mechanical issues can be predicted or quickly diagnosed. The vehicle also becomes much stealthier.

The combination of reduced noise and vibration levels with the smoother ride provides lower rolling resistance at higher speeds. At a vehicle speed exceeding 32mph, rubber tracks typically provided a rolling resistance reduction of up to 50%. This reduces wear and tear of the engine, transmission, and final drives.

The reduced rolling resistance obviously translates into reduced fuel consumption (L/km), leading to an improved, more cost-effective vehicle range.

When considering fuel economy and track durability, rubber tracks usually provide cost reductions of 25% over traditional steel tracks. In addition, man hours are reduced by 53 hours of maintenance per 1,000 miles travelled.

Many mine blast tests have revealed that rubber tracks can withstand a typical anti-personal mine (240g of TNT), whereas traditional steel tracks will separate and create projectiles that worsen mine effects.

In the event that the rubber track would separate and the vehicle is still serviceable, a rubber track repair kit is available.

Composite rubber tracks for heavy vehicles

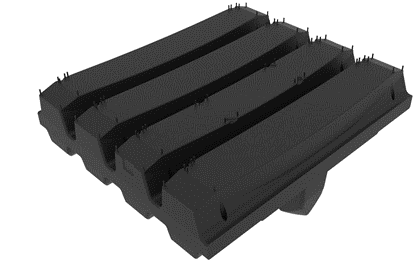

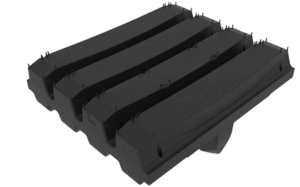

Rubber tracks for heavy vehicles have seamless continuous belting, on which one centre guide lug is located to stabilise the track. See Image 1 below.

To transfer torque from the sprocket to the track, two drive lugs are located on each side of every track pitch. Contact with the ground and soil traction is insured by the rectangular-shaped external profiles. To sustain stress, each component is strategically reinforced.

One important material of a composite rubber track is of course, the rubber compound which represents roughly half the track weight. Overall, a composite rubber track is made of more than 12 distinct rubber compounds, each having different mechanical properties, one of which is the Soucyprene, a Soucy Trade Mark, offering a wear rate of 20 times less than the conventional natural rubber compound.

The chart, as shown in Image 2 below, demonstrates that the Soucyprene offers a wear rate of 20 times less than conventional natural rubber compound (e.g. steel track rubber pads) in a laboratory abrasion test.

Advanced 50mT vehicle technology

Throughout 30 years of research and development (R&D), Soucy’s evolution through the vehicle types and weight classifications is evident as we continually strive for improvement and excellence. Since the official validation of the 39mT product line, Soucy have been developing new and improved 50mT vehicle rubber track technology. This technology will be realised in the very near future, giving Nations of heavier vehicle weight categories the opportunity to experience the advantages of Soucy’s CRT.

About Soucy Defence

Soucy Defense have been manufacturing composite rubber track for defence and security sectors for over 30 years.

The company creates solutions that meet the highest requirements approved by military forces worldwide and are proven in battle conditions during domestic and expeditionary operations.

The group has a diverse set of engineers who work closely with our customers to find innovative high-performance and sustainable solutions to meet their track system requirements, whilst minimising production costs regardless of the scale and complexity of the project.

With so many years of experience within the military sector, Soucy has gained a wealth of knowledge on differing vehicle weights and configurations. This allows for customers to purchase an ‘off-the-shelf’ package or a bespoke package designed for their individual needs.

At Soucy, we are committed to meeting our clients’ requirements and providing products and services that exceed their expectations. We are constantly improving our processes and our products, striving for excellence in everything we do.

Soucy Defence have their own design team that use a variety of tools and facilities to design the products, including:

- 3D scanner: a tool allowing three-dimensional reconstruction of a vehicle to facilitate the analysis and development of products that are perfectly adapted to it.

- Inspection software: used for the identification of variations between the CAD model and the scanner file

- 3D design software: Solid Edge and Unigraphics

- Modelling and finite-element calculation using the Abaqus software.

- A prototyping and modelling workshop allowing the production of a first prototype very quickly.

- Rapid prototyping using 3D printing capabilities

- Design optimisation tool: TOSCA Structure

- Vehicle reference fleet for real-scale testing on 9mT to 45mT military vehicles

Future applications

High-Speed Track

Howe and Howe Technologies have produced a lightweight tank with a speed exceeding any competing land-tracked vehicle. They have implemented the use of Soucy CRT track system within their design.

To watch the high-speed tank in action, copy these links into your browser: www.youtube.com/watch?v=SUBnPAXC1C0 and www.youtube.com/watch?v=Z8uUqdsz78g

Additionally, refer to Image 3 below.

Soucy Defense (Soucy) specialises in advanced composite rubber track (CRT) technology for 45m vehicles.

Soucy Defense (Soucy) specialises in advanced composite rubber track (CRT) technology for 45m vehicles.