Runflat Systems

Runflat Insert Technology for Military Wheels

Run Flat Systems provides insert technology for all deflated tyres on standard single piece drop-centre wheels.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

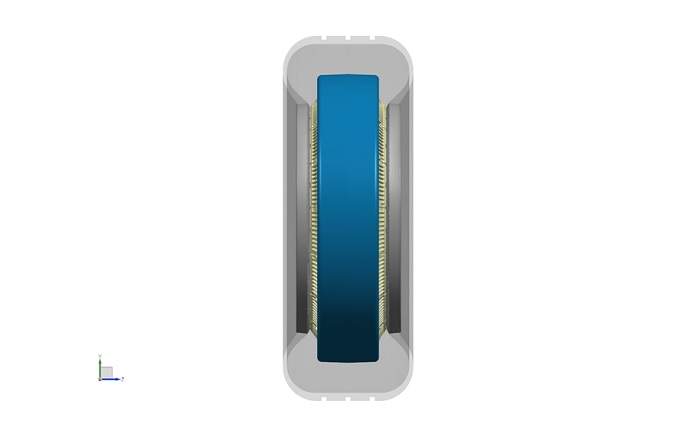

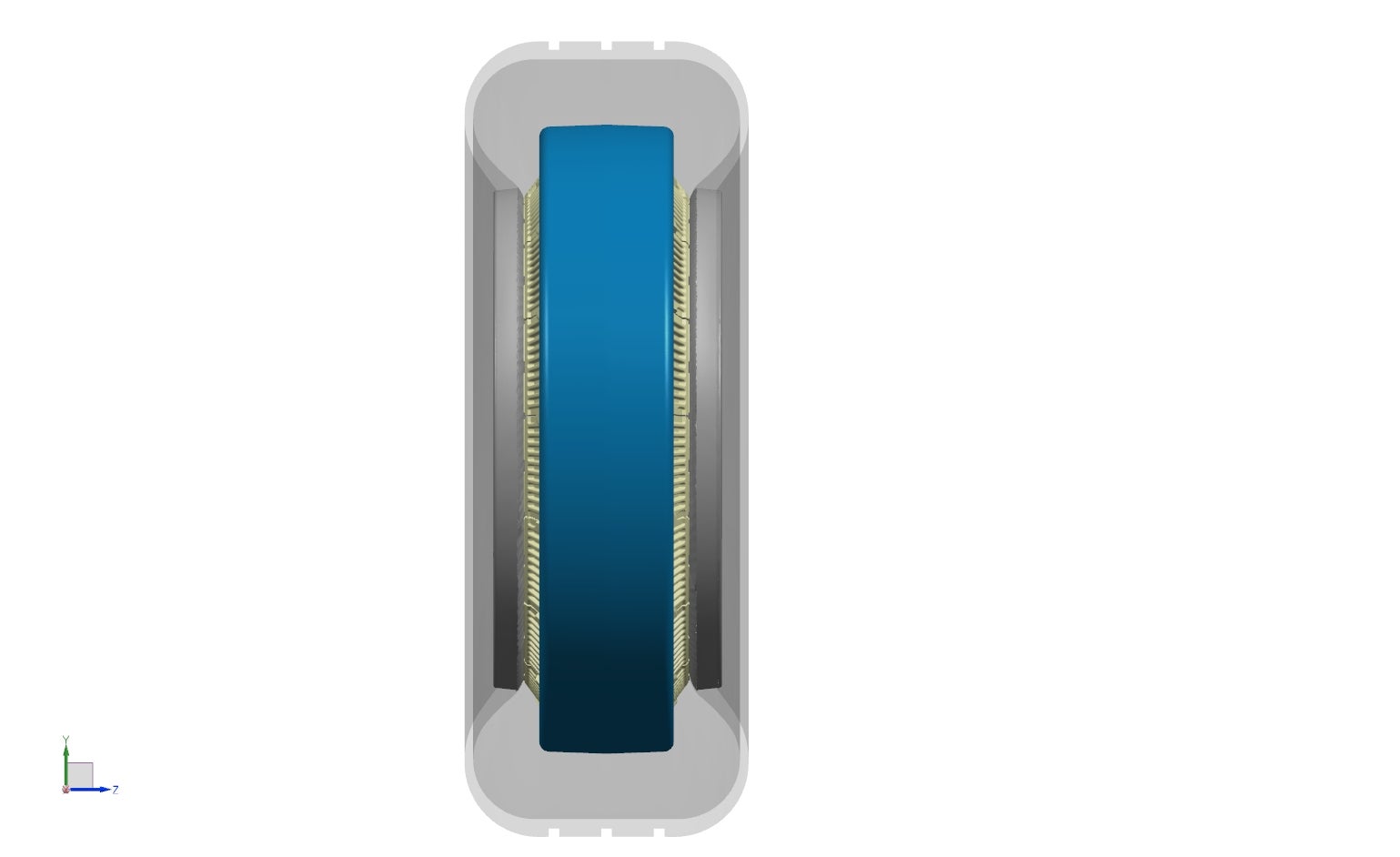

Runflat CBR has introduced a brand new category of runflat insert to the vehicle runflat market. CBR is a combined beadlock and runflat, making CBR the first of a new category of runflat insert to incorporate flat tyre support with full double sided beadlock that can be easily and swiftly fitted to the single piece wheel. CBR brings the advantages of two-piece bolt together wheel and runflat assemblies to the single piece wheel in a significantly lighter and easier to fit package.

This new category employs technological features that make CBR the most advanced system available today and takes runflat performance beyond current industry standards, while introducing all tyres deflated drivability to the single piece wheel. This advancement in the concept of runflat insert capability is unique within the runflat insert market.

A leap forward in the design and functionality for the runflat insert

New runflat insert concepts include a lightweight cantilever design with patented ‘active beadlock’, shock absorption when running flat and a sealed lubrication system. This new technology is set to revolutionise the industry in all fields of on or off-road vehicles, armoured 4×4 vehicles, governmental vehicles, police and security vehicles and all military vehicle runflat requirements currently up to and including 10 x 20 military truck sizes.

CBR runflat inserts include shock absorption capability when running flat, helping protect suspensions and wheels while giving a better performance, especially off-road. Sealed lubrication systems mean clean tyre replacement or repair, saving time, inconvenience and cost. CBR Extreme features an outer anti-friction component that provides it with world beating long distance runflat.

CBR disrupts the traditional runflat insert market

CBR technology is set to disrupt the runflat industry by removing the need for two-piece bolt together or specialist wheels, necessary to carry systems that incorporate beadlock within their construction, meaning these wheel types are no longer an absolute necessity because CBR can be swiftly fitted inside normal single piece wheel and tyre combinations with all the advantages of the two-piece wheel and runflat combination, including full beadlock, that provides the ability to run at low pressures or to employ CTIS.

The ability to use normal single piece wheels offers a capital cost reduction. Steel or alloy wheels can be used, either standard OEM or aftermarket.

A lightweight wheel and runflat insert combination

Light weight has been a primary objective in the design of CBR and its cantilever construction ensures it is the lightest runflat support with beadlock. Another ground-breaking contribution to reduced weight is that single piece wheels can now be used for best performance rather than the significantly heavier bolt together and specialist types.

Heavy duty or uprated and therefore heavier single piece wheels are often used on armoured and uprated vehicles, partly due to current state-of-the-art runflat inserts fitting on the wheel’s centre section, an area not designed to carry these loads when running flat. CBR sits adjacent to the tyre bead seats where the wheel can properly carry the extra loads when running flat, in many cases allowing the use of standard or OEM wheels without the need or extra weight of reinforced alternatives.

Proven best performance in many applications

CBR has conclusively demonstrated the best performance capabilities on the single piece wheel. All CBR types are unique in providing all tyres deflated performance on the standard single piece drop-centre wheel and both types have proven ‘J’ Turn and evasive driving capability, with one or all tyres deflated.

CBR Extreme is PAS 301 certified through Millbrook / UTAC CERAM. Finabel tests are exceeded by all CBR types and with all tyres deflated, not just the two specified by Finabel. CBR Extreme surpasses Finabel A.20.A at 150km. Tests at IDIADA’s test facilities in Spain have proven runflat distances in excess of 250km.

The introduction of CBR’s new category of runflat insert brings the performance and capabilities of runflat inserts into a new dimension. Its performance is further enhanced with unbeatable unsprung weight for a wheel and runflat with beadlock

Refined fitting

Fitting CBR is simple and fast and tyres can be mounted on the single piece rim, along with the runflat, using tyre fitter’s normal hand tools or tyre fitting machines.

Contributing to runflat technology since the 1980s

The CBR team is not new to the industry with engineers who have had continuous runflat experience since the late 1980s and already contributed to runflat technology worldwide, including products in use today. To turn the CBR concept into a commercially viable product has required considerable financial investment and an expanded team, bringing in new talent, a fresh approach and engineers qualified in the aerospace industry and at Ferrari’s Formula-One team.

Contact Details

Website

Address

First Avenue,

Auckley,

DN9 3QZ,

Doncaster,

United Kingdom