MKU offers complete project management for design, development, manufacturing, and integration of protection solutions for Land, Air and Naval platforms using special patented technologies and systems which have been developed over years of R&D efforts.

MKU is uniquely capable of processing both soft and hard armour, either alone or in combination, under the same roof. A team of qualified engineers, certified quality inspectors, weapon specialists, and ex-servicemen in India and Germany have pooled their collective experience and expertise to ensure precise solutions. The 4-stage process followed at MKU is designed to address all queries and examine all criteria required to manufacture and integrate protection solutions as per customer requirements.

Why is lightweight armouring important?

Although steel has been the traditional choice for ballistic protection for quite some time, the changing combat applications demand more protection. The ever-increasing lethality of modern ammunition has raised serious doubts in recent times on the versatility of steel alone to overcome the performance and survivability of expensive vehicles of today. Some of the benefits of using lightweight armour solutions are listed below:

- Low GVW (Gross Vehicle Weight)

- Increased fuel efficiency

- Better power to weight performance ratio

- Higher payload capacity

- Increased inertial energy

- Increased vehicle mobility

- Reasonable maintenance costs with regard to mechanical, structural & operational parameters

- Easy to install

- Higher durability

- Reduced vibration

- Quick adaptability to diverse mission requirements

- Low thermal signature

- Low in-cabin air-conditioning requirements

- Rich acoustic properties

Complete project management

4 Stage Process for End-to-End Solutions

Kavro Platform Protection follows a 4-stage smart process that is proven to ensure efficient project management and offers end to end solutions for lightweight composite ballistic protection of platforms. This process is designed to address all queries and examine all criteria to develop efficient and optimised protection solutions per customer requirements.

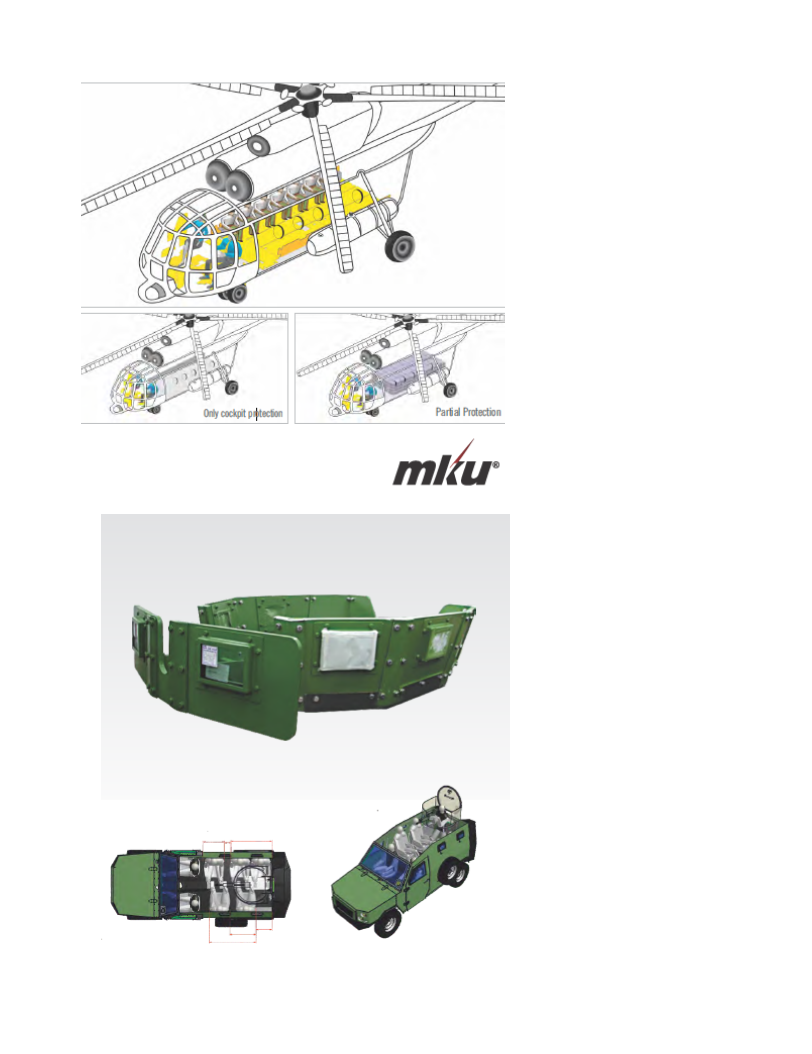

Land protection

Armouring in a land vehicle is essential for providing protection from a variety of weapons and maintaining operational independence in a hostile environment. Add-on armor can be used to effectively enhance the security level of existing and new platforms. MKU’s lightweight armor solutions help reduce the added weight penalty, which allows even lighter vehicles to achieve a higher level of protection without losing maneuverability.

Aircraft armouring

Safeguarding the highly trained aircrews and sophisticated machines is the most important factor, that’s why we at MKU developed unique technology Modulare Schutz Technik for armouring of helicopters keeping their multi role operations in mind. It uses special kits comprising of precision engineered composite armour panels along with patented aero-grade attachment systems. These kits are simply installed upon the existing structure of the helicopter without requiring any structural changes or tampering with the Aerodynamics of the platform. Depending upon the mission requirements, these kits can be easily and quickly deployed in, or removed from the aircraft either in part or in full without the requirement if any special tools.

Naval vessels

Providing Integrated Ballistic Protection in all critical areas of a naval vessel by matching the complex contours of the ship’s shape is a difficult task in itself. MKU provides customized light armor solutions for all types of small and large naval vessels, including hovercraft, frigates, corvettes, OPVs, yachts, petrol boats, FICs and RIBs. MKU’s end-to-end services are most prominent for integration and customized solutions to most of the threat scenarios prevailing at present. Ballistic protection can be integrated into the vessel during construction or added later, depending on the customer’s requirements.

Threat assessment and platform evaluation

Experts from MKU’s team first assess the customer’s protection requirements and the theater of operation of the platform that is to be protected, including its operational restrictions. MKU then prepares and delivers a systematic report on its assessment of the threat, platform capability, and operational restrictions.

Locations And Areas For Light Weight Armour Protection:

- Wheel House

- Bridges

- Doors & Windows

- Command & Information Centers

- External Weapon Positions

- Fuel Tank

- Missile Launch Silos

- Ammunition Storage Compartments

- Gunner Ports

- Engine Room

- Kitchen

- Other Critical Areas

Threats & Standards Covered

MKU offers armor solution against almost all prevalent Ammunitions and Threat Standards:

Ammunition/Threats

- Fragments from anti-ship missiles

- Armour piercing rounds from aircraft cannon

- Heavy Machine Guns

- Small arms round

- Explosive blasts

Design -> Prototyping -> Manufacturing -> Integration

- Solution Design

- Threat Analysis

- Platform Assessment

- Payload Assessment

- Protection Area Assessment

- Performance Analysis

- Budgetary considerations

In the solutions design stage, experts from Kavro’s solutions team assess the protection requirements, theatre of operation of the platform that is to be protected, including its operational restrictions. They then prepare a systematic report on their assessment of the threat, platform capability and operational restrictions.1

- Solution Development

- Solution Development

- Prototype Development

Upon completion of the solutions design stage, the Kavro technical team works on carefully selecting the materials based on protection, performance requirements and any other specific requirements captured during the solution design stage. The Kavro engineering team meanwhile starts developing an engineered prototype for the solution and custom fitments to ensure compatibility, coverage and integration criteria.

- Manufacturing

Depending upon the final selection of the solution, Kavro Platform Protection manufactures a comprehensive range of products and solutions that cover a large spectrum of lightweight armour solutions and protection solutions for naval platforms, air platforms, land vehicles and objects including:

- Engineered Armour Kits

- Engineered Composite Armour Panels

- Engineered Flexible Armour Panels

- Add-on Armour

- Spall Liners

MKU’s Specification

MKU ballistic solutions are IMO and MIL-STD 810G compliant which can be mounted from the inside or outside. Multi-Hit Enabled Solution (AEP-55) are fasteners specially developed for naval vessels. MKU has a large number of unique, distinctive, and patented attachment systems and fittings for the purpose of integrating and fitting its lightweight armour kits onto land, air, and sea platforms. These attachment systems have been tested rigorously to withstand the extreme pressures of the platform’s maneuvers under extreme conditions.