Researchers at The University of Massachusetts Lowell are using sustainable green chemistry to improve the fabric the US Army uses for soldier uniforms.

Uniforms are currently made of a material that is inexpensive, durable and comfortable in all climates, however, it is neither fire-retardant nor insect-repellent.

The researchers focussed on these two properties in their experiments and are due to present their findings at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo this week.

Study leader Ramaswamy Nagarajan PhD said: “The Army presented to us this interesting and challenging requirement for multifunctionality.”

There are currently no existing materials that incorporate all of the properties necessary for safe uniforms. It is expensive to create a new material that is simultaneously multifunctional, easy to dye and consists of raw materials that the US produces.

The researchers, therefore, decided to develop an existing commercially available and inexpensive material made of a 50-50 nylon-cotton blend produced in the US.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe nylon in the blend makes the material strong and resistant to abrasion and the cotton makes it comfortable. However, the material does not repel insects and poses a high fire risk.

The researchers focussed on sustainable green chemistry in this study, using non-toxic chemicals and processes to imbue the material with fire-retardant and insect repellent properties.

The scientists first tried to make the cotton fire retardant. PhD student Sourabh Kulkarni explained:

“Cotton has a lot of hydroxyl groups (oxygen and hydrogen-bonded together) on its surface, which can be activated by readily available chemicals to link with phosphorus-containing compounds that impart flame retardancy.” The researchers chose phytic acid as their phosphorous-containing compound for its non-toxicity and abundance.

The team next tried to make the nylon insect-repellent. They collaborated with LaunchBay to attach a non-toxic insect repellent called permethrin to fabric through a method known as plasma-assisted deposition, where plasma is generated between the repellent and the fabric that helps it attach as a thin film.

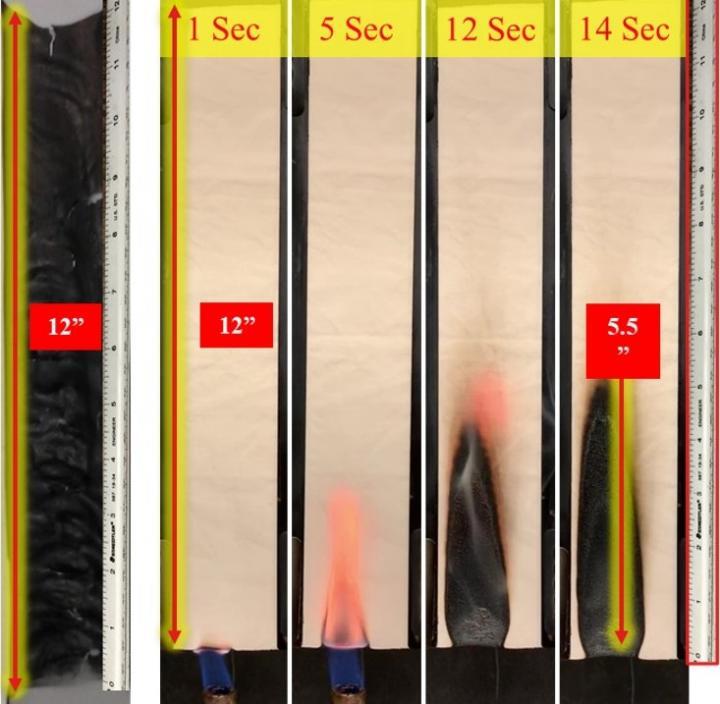

The study revealed that the adapted material performed 20% better than untreated material in heat tests and was over 98% more effective in standard insect repellence tests with live mosquitos.

The researchers plan to experiment further with a non-toxic substance other than phytic acid to achieve greater flame retardancy. They are also considering attaching antimicrobials to prevent infections from bacteria and dyes that remain durable.

By Emmaleigh Eaves