Armed forces personnel is exposed to significant amounts of noise throughout their service life: from the big bangs and blasts produced by high-frequency impulse noises such as gunfire, artillery, improvised explosive device blasts or other percussive sounds to extended periods exposed to the buzz, whir and beep of low-frequency constant noise while traveling in helicopters or armoured vehicles or operating machinery, all these sounds leave their mark on the auditory system.

For many decades, the issue of hearing loss amongst soldiers has been considered something of a standard occupational hazard, or a ‘hidden injury of war’. However, while personnel who leave the forces without serious injury may consider themselves lucky in the short term, the long-term effects of hearing damage can seriously impact quality of life, mental health and career prospects and future earning potential for the worse.

In 2014, the Royal British Legion published a report, titled ‘Lost Voices’, into its findings on hearing loss among service personnel and veterans. In short, the report found that veterans under the age of 75 are “about three and a half times more likely than the general population to report difficulty hearing”. Its survey found that 11% of surveyed veterans reported having problems hearing and 6% reported tinnitus, equating to over 300,000 ex-service personnel living with hearing loss. Personnel who have served in recent conflicts appeared to have an even higher rate of audio trauma, with tests on infantry troops returning from Afghanistan in 2007/08 indicating that up to 14% had suffered hearing loss.

The Royal British Legion’s work here does not stand alone, with the issue of hearing loss amongst service personnel being addressed by a number of organisations over recent years. In the UK, the Ministry of Defence has put in place a number of initiatives to improve its duty of care to prevent injury using protective measures in the field, and a number of preventative solutions are being rolled out to soldiers, such as the Tactical In-Ear Protection Plugs for the MoD’s Tactical Hearing Protection System for the Basic User Soldier requirement – contracted to MCL in 2015.

Innovative solutions

Research into possible solutions has also been taken up by wider industry and research bodies, including Nottingham Trent University (NTU), which is working on a new technology to measure and record the levels of noise which soldiers experience in the field to prevent hearing damage.

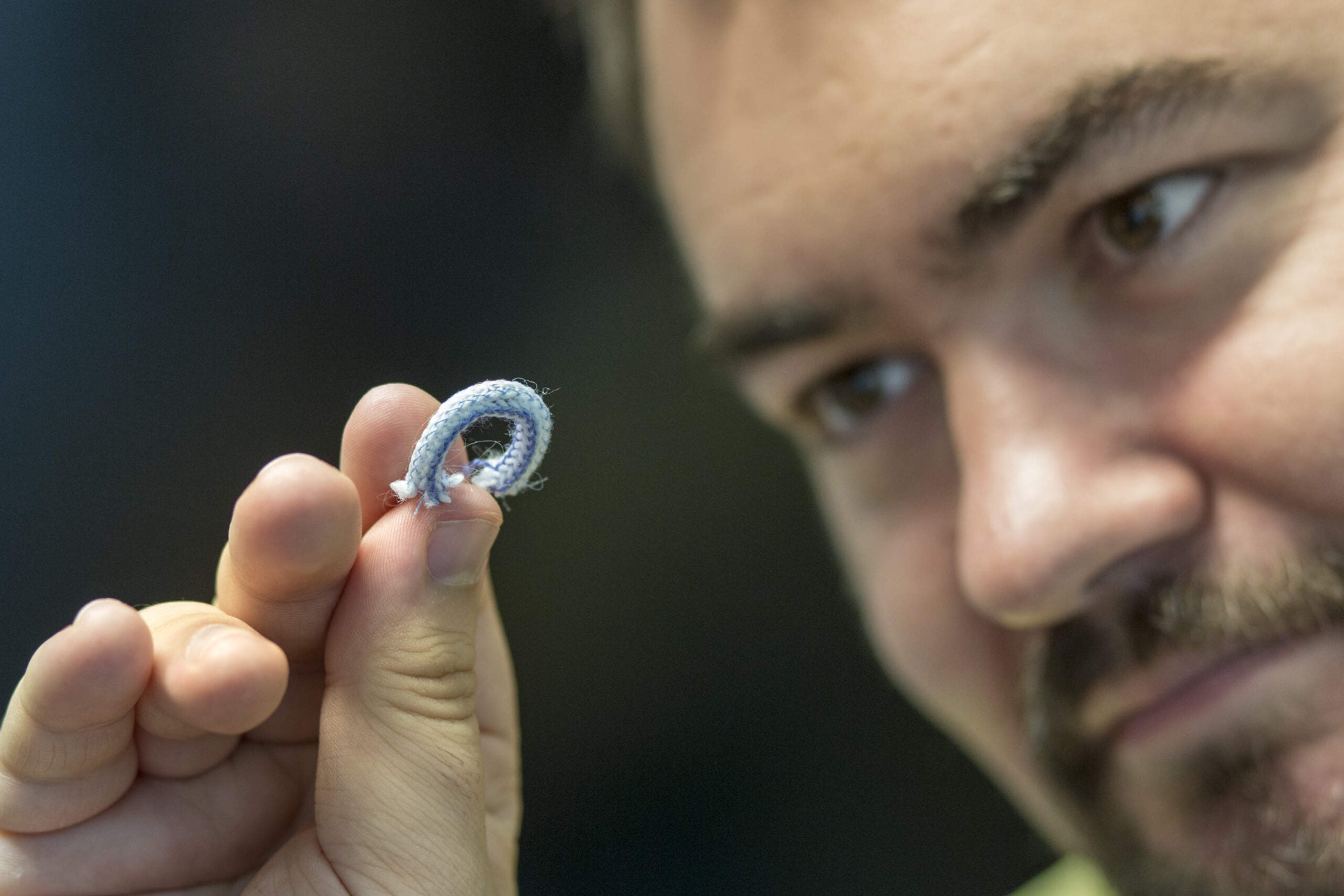

The project, led by NTU’s Advanced Textiles Research Group (ATRG) of the School of Art & Design, is using microelectromechanical system microphones (MEMS) which measure the level of noise someone is exposed to over a length of time. When knitted into the fabric covering regular personnel headwear, these microphones will monitor and store data on the noise exposure of personnel – while being undetectable to the user and avoiding interfering with military activities – in order to provide the data necessary to take preventable action in the future.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe system is based on an ATRG patented core technology that allows the integration of small electronic components into yarns.

“We are interested in exploring the various options that we can exploit with this. As a result, we conducted some very preliminary work on creating acoustic monitoring yarns by integrating MEMS microphones into yarns,” Dr Theodore W.B. Hughes-Riley, research fellow in energy harvesting and management in textiles at ATRG, said. “Once we knew that this was viable we applied for, and successfully received funding from Dstl, via the Defence and Security Accelerator, to develop the yarns for use as a noise dosemeter for service personnel.”

The main objective of the ATRG’s work is to develop a prototype noise dosemeter that is integrated as part of a standard helmet cover – or smart helmet. The complete textile helmet cover will have two acoustic sensing yarns, one over each ear.

“To achieve this objective we have to develop and characterise the acoustic sensing yarns, as well as produce suitable supporting hardware and software to analyse the collected signals,” Hughes-Riley said. “The ATRG is drawing on previous experience of integrating sensors into yarns, including the development of vibration sensing yarns and temperature sensing yarns.”

The position of the yarns over each ear is important, as having the sound recording element as close to the ear as possible will provide the most representative measurements. Additionally, an acoustic injury is more likely to be asymmetric during military activities, meaning one ear might be affected more than the other.

The acoustic yarns will be attached to a small recording module which will store data. The data will then be downloaded from the module for processing and analysis elsewhere. ATRG is currently looking at two completely independent modules (one for each ear), which provides some degree of redundancy.

The microphones will be embedded in yarns using ATRG’s e-yarn technology platform to keep them dry and allow the helmet covers to be washed.

Looking ahead

UK service personnel are not currently equipped with a noise dosemeter, and it is hoped that the use of this technology will help ensure that potential hearing problems in service personnel are picked up as early as possible.

The ATRG is currently finalising aspects of the acoustic sensing yarn; once this has been completed it will proceed to integrate the yarn into a helmet cover that could one day form part of a piece of standard equipment for personnel, although there are currently no plans for this.

NTU is hopeful that in addition to preventing injury, the helmet will make it simpler for the military to continue to fully comply with the Control of Noise at Work Regulations which limit the level of noise that an employee can be exposed to in the workplace over a period of time. With hearing loss impacting an individual’s speech comprehension and ability to communicate with others, it has a profound impact on quality of life – making it so important that soldiers are given the best protection possible to prevent them experiencing noise levels which can cause injury.