Viscom

Inspection Technologies for Defence and Other Applications

Viscom AG designs and manufactures inspection solutions that include optical and X-ray inspection.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Inspection solutions for mission-critical electronics

Headquartered in Hanover, Germany, and with more than 40 years of experience, Viscom has been at the forefront of helping clients achieve 100% fault-free products through inspection solutions for a wide range of applications. For defect-free electronics, Viscom designs and manufactures inspection systems that protect equipment for critical missions.

As performance and safety challenges can be caused by even the tiniest defect, Viscom makes sure that equipment is safe and durable by safeguarding its components through inspection technology. These are purposed for demanding environments and ensure mission readiness by helping detect and eliminate any hidden problems.

Precision technology for mission success

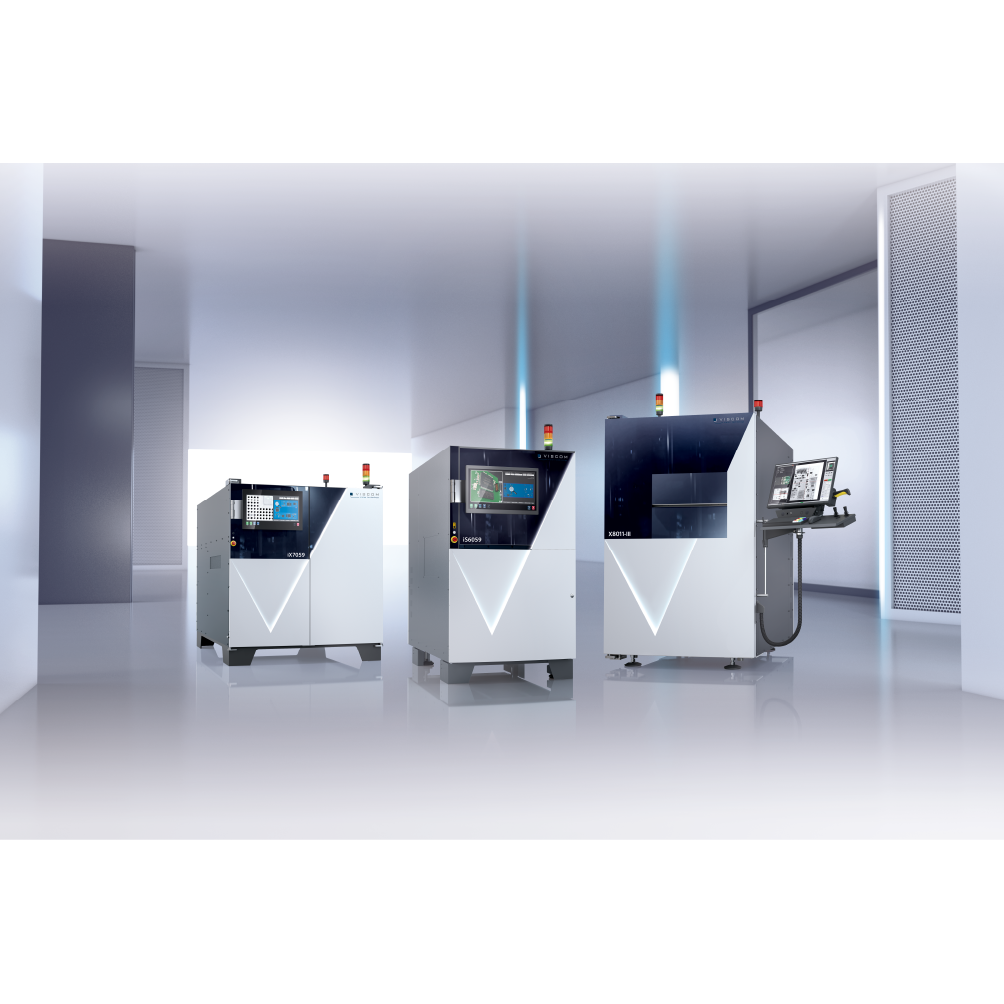

Viscom boasts a diverse portfolio of inspection solutions adapted to the needs and challenges of critical electronics. The company’s inspection technologies are used to reveal defects, ensure structural reliability, and confirm product quality before any application.

Viscom’s products and solutions are crucial for inspecting electronic assemblies and detecting any faults that can compromise product integrity. Especially with modern electronics, which consist of smaller, more complex components that are densely packed, complexities can arise through hidden features that can compromise safety and product reliability. Viscom addresses these challenges through high-quality inspection systems that reveal these issues.

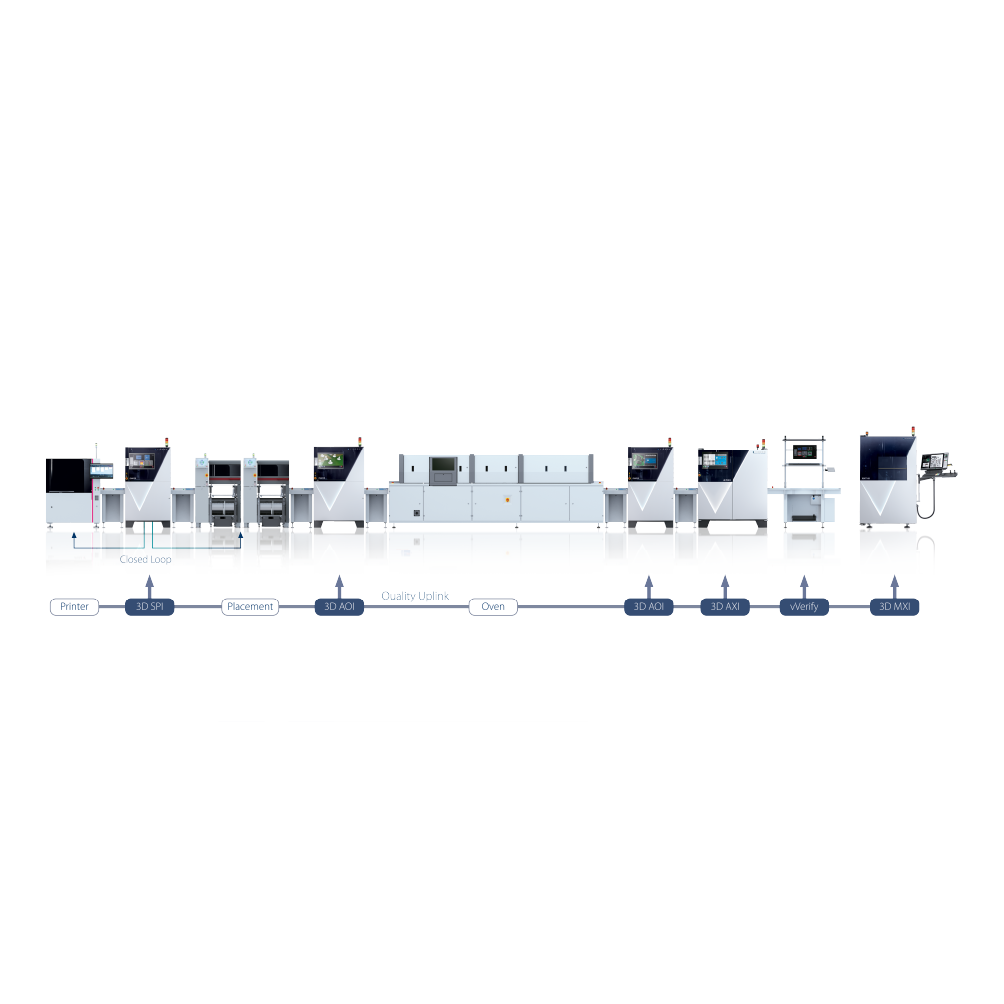

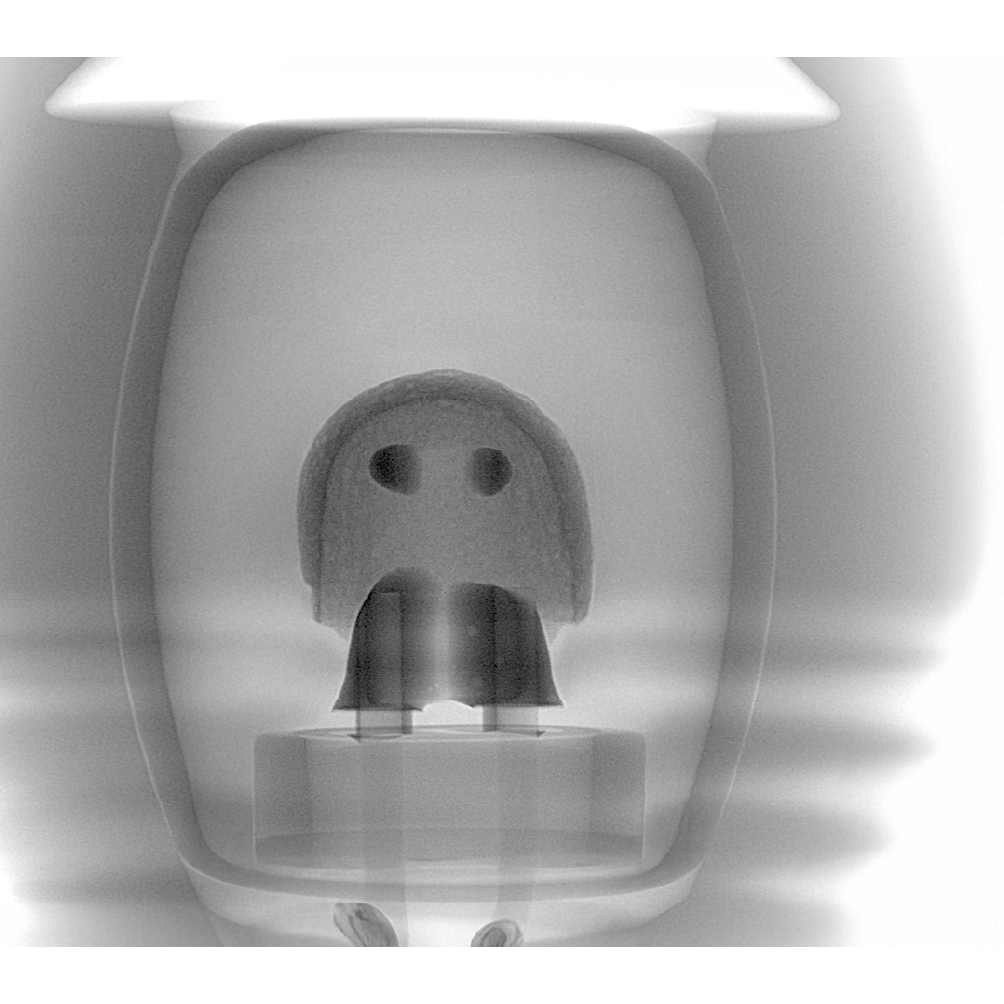

AOI technology employs optical inspection to discover surface-level problems such as faulty components, missing parts, or defective solder joints. X-ray technology is used through AXI systems to investigate the inside of assemblies that are not visible from the outside; these can include voids inside solder joints or hidden electrical connections.

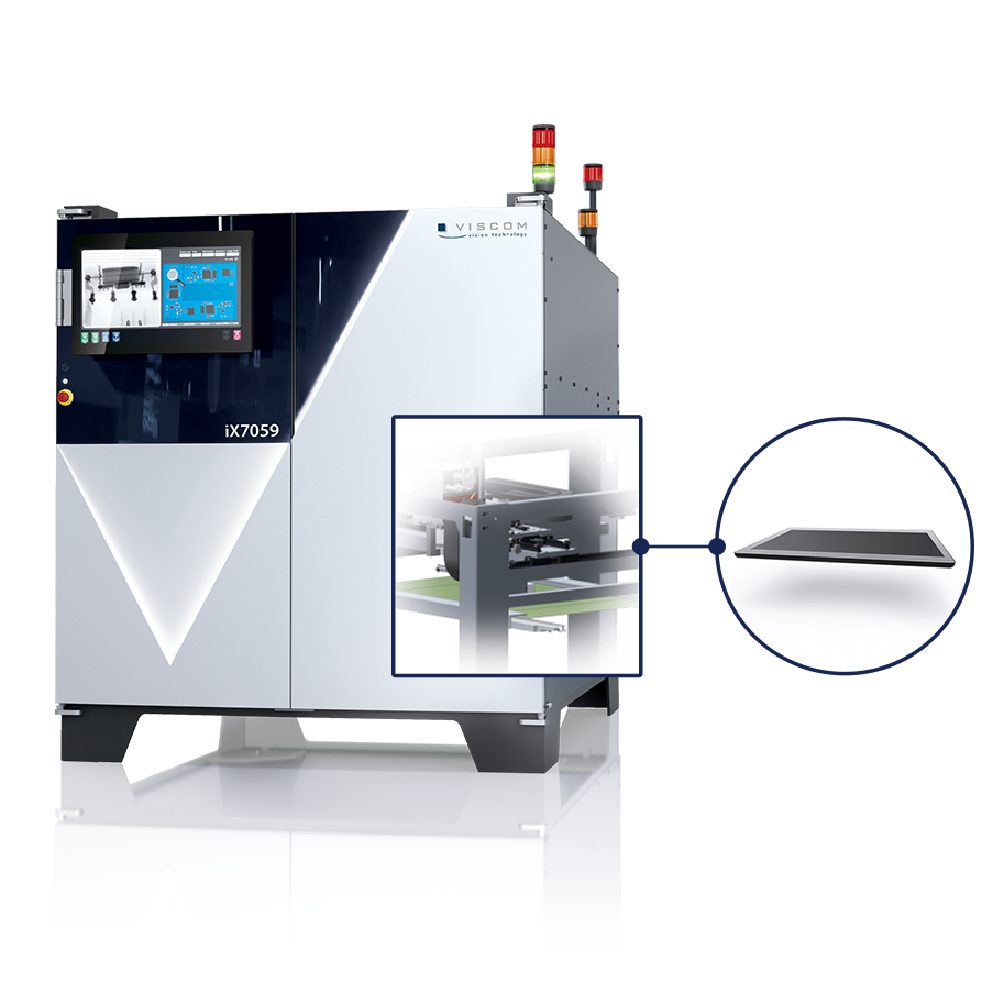

MXI tools allow engineers to maintain control over complex electronic assemblies by using manual X-ray, which renders these solutions perfectly suitable for research and development (R&D), troubleshooting and failure detection, as well as specialised high-mix, low-volume production. Viscom’s advanced X-ray technology, which includes the in-house development of the company’s very own X-ray tubes, makes sure that all supply chain steps are safe and secure.

Viscom: Made in Germany. Trusted Worldwide.

Viscom’s products and services are rooted in German engineering, which promises precision, durability, and pioneering technologies that are standard. All inspection systems are designed and manufactured in-house to ensure the best possible quality, and all materials and other parts are mainly supplied from Germany and the EU.

Our commitment to excellence is the main reason international OEMs, Tier-1 suppliers and defence contractors trust Viscom for the high standards of its services and solutions.

Our inspection platforms consist of high-quality, high-performance imaging, advantage optics, intelligent algorithms, and robust construction that yield measurable and reliable results even under the harshest environments. Through every step of the supply chain (evaluation to full-scale production), Viscom’s systems offer clients the actionable insights that they need for product integrity.

Viscom: Safeguarding mission-critical success

Mission-critical sectors require more than a quality check: they need safety against operational risk. Viscom is committed to providing the highest possible quality, reliability and durability for all its products to ensure a safe and smooth electronic assembly.

Defence and aerospace particularly require electronic systems that are durable against shock, vibration, extreme weather conditions, electromagnetic interference, and more. The outcome is mission readiness, operational efficiency, equipment durability, and lower long-term risk.

Viscom is trusted by clients globally and makes sure that each customer receives the best support wherever they are based. Supporting our clientele includes initial consultation and system integration, and extends to services such as training, optimisation, and long-term service, enhancing inspection accuracy through comprehensive customer assistance. Advanced inspection hardware and in-depth expertise are at the core of sustainable excellence in every Viscom solution, even for the most complex production lifecycles.

Shaping the future of inspection

With head offices and main production facilities in Hanover, Germany, Viscom combines innovation with top-quality precision manufacturing to guarantee its solutions meet the highest standards globally. Its inspection offerings inspire confidence even in the most complex assembly cases.

With the rapid evolution of technology comes the need for accurate and reliable mission-critical electronics, along with intelligent inspection systems that can enhance and support these processes. Viscom is a leader in supporting manufacturers and defence organisations through expertly engineered inspection that boosts product integrity and facilitates safe supply chains. German engineering is combined with innovation such as state-of-the-art AI solutions, to accelerate the reliability of mission-critical protection systems.

Contact Details

Website

Email Address

Address

30455,

Germany