Viable Power Conversion Technologies

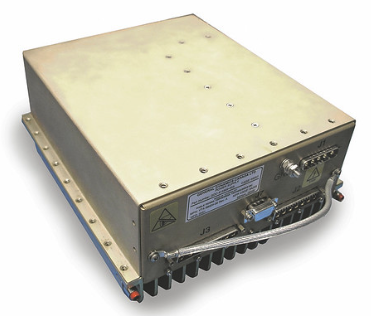

Ruggedised Custom Power Supply Solutions for Defence Applications

Viable Power Conversion Technologies (VIABLE) specialises in designing and manufacturing custom-made, highly reliable power conversion solutions with quick turnaround times.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Viable Power Conversion Technologies designs highly reliable custom power conversion solutions for defence, aviation, and naval applications.

We have been designing custom ruggedised AC-DC and DC-DC power solutions and power system accessories for the military and commercial sectors for more than 25 years. We are ISO 9001:2015 and AS 9100:2016 certified and registered with the Joint Certification Program (JCP).

Our expertise, combined with our design approach, allows us to offer fast turnaround times from design to testing and manufacturing of our custom power supplies.

Custom power supply units for the defence industry

All our custom power supply units meet the requirements of MIL-STD-1275, which define the interface characteristics of 28Vdc Input Power to utilisation equipment in military vehicles.

Using industry-standard power converter modules from a wide range of reputable manufacturers, we’re able to develop custom power solutions that meet all of our customers’ requirements.

We rigorously inspect the quality of our products during the manufacturing phase, then conduct a series of performance tests, including vibration and thermal cycling tests, which enable us to deliver quality products that will operate for many years to come.

Custom DC Power Supplies

DC-DC power supplies for military ground defense, and specifically for ground defense vehicles, have very specific design requirements. In addition to the electrical input requirements and the fact that they must operate from a vehicle battery, these custom power supplies are subject to extreme environmental conditions such as temperature and vibration.

Meeting the input requirements of MIL-STD-1275 for ground vehicles, Viable Power’s DC-DC custom power supply units can be designed to meet specific form factor and environmental requirements. They normally operate from 28V sources, but we can also design other input voltages for specific applications. Power levels of our custom DC-DC power supplies range from 5W to over 2KW. Custom linear or standard DC-DC power modules and custom or standard EMI filters from leading manufacturers are used in the design of our custom DC-DC power supplies.

Uniquely packaged in accordance with the customer requirements and hermetically sealed, our custom power supplies go through a series of tests from qualification tests to environmental stress screening tests which include vibration and thermal cycling.

Custom AC-DC Power Supplies

Viable Power designs custom AC-DC power supplies for ground, naval, and air defense applications with power capabilities ranging from 20W to several KW. Operating from 115V, 400Hz three-phase sources and 115V, 60Hz single-phase sources, our AC-DC power supplies meet the input requirements of MIL-STD-1399, MIL-STD-704 or RTCA DO-160 depending on the application.

Each AC-DC power supply design includes EMI filtering, a three-phase or single-phase rectifier depending on the input source, bulk internal capacitance, and a suite of DC-DC power converter modules with output filtering. We can also design and package each AC-DC power supply unit to meet specific requirements such as environment and space.

Custom power supplies for industry-specific requirements

Viable Power specialises in designing custom power solutions to meet specific requirements. Whether it’s a specific performance characteristic, application environment or packaging constraint, or a combination of all three, we can design the right power supply for you.

Viable offers high-reliability custom power conversion solutions with a fast turnaround time for the military ground defense, aviation, and naval sectors.

All our custom power supplies meet the specific requirements of one or more of the following standards depending on the type of application: MIL-STD-704, MIL-STD 1399 Section 300, MIL-STD-1275, MIL-STD-461, RTCA-DO-160, MIL-STD-810, MIL-HDBK-217F N2.

Contract manufacturing of custom power supplies

To cater for the unique demands of our customers, we provide the opportunity to subcontract through us the manufacturing of electronic components or specific products for low to medium volumes. Our knowledge and equipment allow us to offer a turnkey service covering all the details, from their order to the delivery of the final item.

About Viable Power Conversion Technologies

Viable Power Conversion Technologies designs and manufactures its power supply solutions in its 7,500ft² facility equipped with wave soldering and PCB (printed circuit board) washing machines, wire cutting, stripping, and crimping machines, and electron microscope inspection tools. Our automated test equipment (ATE) allows us to test power supplies with up to 8 output channels. We perform on-site environmental stress screening and vibration testing with our high ramp rate temperature and humidity cycle test chambers and electrodynamic vibration system.

Our highly skilled production staff, trained in accordance with IPC-J-STD-001, perform all work at Class 3 levels. We perform inspections according to IPC-A-610 Class 3 and every mechanical assembly meets the guidelines of MIL-HDBK-454.

Contact Details

Website

Email Address

Address

Pointe-Claire,

Quebec,

H9R 4X5,

Canada