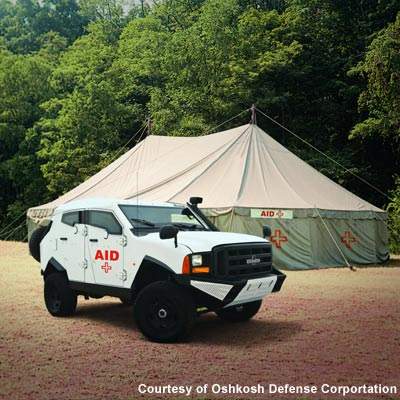

The Oshkosh SandCat protected multirole vehicle.

The Oshkosh SandCat is a protected multirole vehicle built to offer high performance and payload capacities for challenging missions. Manufactured by Oshkosh Defense, a division of Oshkosh Corporation, the vehicle was demonstrated at the Defence Vehicle Dynamics (DVD) event on 25-26 June 2008.

The vehicle is designed to serve as a versatile, highly protected, manoeuvrable and affordable solution for a variety of missions, including military, special operations, peacekeeping, law enforcement and security, homeland defence and disaster aid.

SandCat mutlirole vehicle development

Plasan of Israel initially designed SandCat as a composite armoured vehicle as a replacement to the AIL storm jeeps of the Israel Defence Force (IDF). In October 2005, this vehicle was first demonstrated at the Association of US Army (AUSA) show. Plasan named the vehicle SandCat and displayed it at the Eurosatory show during 2006. At the Eurosatory show in 2008, the SandCat was relaunched as a brand of Oshkosh Defense.

SandCat orders

Oshkosh Defense offers and supplies the SandCat to customers worldwide. Various military and security firms have purchased and fielded the vehicle. The British Army considered the SandCat as it looked to acquire up to 400 new light protected patrol vehicles under the Light Protected Patrol Vehicle(LPPV) programme, before deciding to choose the Ocelot. Oshkosh Defense also submitted the SandCat for the Australian Defence Force’s (ADF) 121 ‘Overlander’ phase 4 programme and the Dutch wheeled vehicle replacement programme.

SandCat features

The Oshkosh SandCat is built on a commercial Ford 550 chassis, allowing for rapid manufacturing and customisation of the armour system to meet the needs of the mission.

The vehicle is 198in long, 85in wide and 88in in height. It has seating for four to eight in two of its variants and has four side doors to provide access. It is fitted with dual fuel tanks with a total capacity of 120l.

The gross vehicle weight rating (GVWR) of the vehicle is 8,845kg. The SandCat can reach a maximum speed of 120km/h. The utility variant can carry a payload of up to 2,109kg, the transport variant up to 1,814kg and the special operations vehicle (SOV) variant up to 2,300kg. The part-time four wheel drive provides the vehicle a turning radius of 6.5m.

The differential locks in the rear are limited slip differential and the front are air lock (ARB USA). The vehicle has ventilated disk brakes and the tyres are 285/70 R 19.5.

Various optional features that can be fitted to the SandCat include: gunner protection kit, remote weapon station, nuclear biological chemical (NBC) safety system, open cargo bed / storage area (non armoured), open cargo bed, self-recovery winch, run-flat tyres, trailer hitch / pintle, rear view camera, external intercom system, airbag system, and an air-conditioning system / heater. The vehicle is also configurable to an ambulance variant with three litters.

SandCat mission variants

SandCat has three variants, utility, transport and SOV, offering customisable protection features. The utility and transport variants can carry a crew of up to five and eight, respectively, while the SOV can carry four.

The utility variant has a curb weight of 6,033kg and a payload capacity 2,109kg. The transport variant has a curb weight of 6,930kg and a payload capacity of 1,814kg. The SOV variant has a curb weight of 5,000kg and a payload capacity of 2,300kg. The payload capacities can vary based on the installations of the protection levels.

Defence

The SandCat is manufactured using a standard, factory-installed ‘A kit’ armour system, which is low in weight and enables less consumption of fuel. It is the base-level metal composite unit. The ‘B kit’ armour is a composite-armoured solution fitted in addition to the ‘A kit’ for a higher ballistic protection. These kits are flexible enough to be assembled in the field.

The cabin is designed in such a way as to protect from shrapnel and fragments or small-arms attacks. It has a superstructure of armour panels with three layers: external layer, wall and spall liners. The external layer, consisting of ceramic segments, is packed into panels that form the foundation of the armour. The wall is the middle layer, giving support to the inner and external layers. The inner layer of the cabin has spall liners that reduce the number of fragments from an external blast.

Survivability

The SandCat has an integrated survivability system comprising of various technologies that are interlocked to each other, forming one complete and integral unit. The technologies of this system include a v-shaped belly plate, impact-absorbing seats, advanced suppression systems and composite materials to absorb and deflect the impact of blasts.

The v-shaped belly plate absorbs the impact of any blast and diverts the energy outward providing protection from mines, buried charges and underside shrapnel.

Another safety feature is the impact-absorbing seating. They are designed to absorb the impact of a mine blast’s vertical influence through a downward motion. This seat base acts as an energy-absorbing spring during an attack and remains stable in normal driving conditions.

The vehicle is fitted with advance suppression systems for the seats that minimise the impact of the blast on the crew. The seats can be suspended in such a manner to that can prevent the contact between crew and vehicle belly during an impact.

An additional SandCat safety option is a five-zone fire-suppression system, which provides immediate protection to all forms of hazardous combustions in the crew compartment, engine compartment, fuel cells, wheel wells and the vehicle’s exterior.

The vehicle also can be equipped with a nuclear, biological and chemical (NBC) safety system for further crew protection.

Ford 6.4l diesel engine

The SandCat runs on a Ford 6.4l diesel engine that generates 325hp at 3,000rpm. It is fitted with an Allison 2000 series automatic transmission and has a two-speed electronic transfer case. The engine complies with Nato emission regulations and has a power-to-weight ratio of more than 36hp/t.

Mobility

The vehicle is built to meet combat and peacemaking missions in urban or remote areas. The hydraulic power-assist, recirculating ball steering creates a turning radius of 6.5m. The vehicle has a track of 73.2in. At maximum payload, the SandCat can climb vertical obstacles up to 18in and side slopes of 39°. It has an approach angle of 38° and departure angle of 30° off-road.

The SandCat has a ground clearance of 13in. It can be easily transported in a C-130 aeroplane and up, or CH-47, MH-47 and CH-53 helicopters.