CeramTec-ETEC, established in 1982 and based in Lohmar, Germany, is part of the CeramTec Group.

The company specialises in the design, manufacturing and supply of high-performance armour ceramics, based on alumina and silicon carbide for body and vehicle protection.

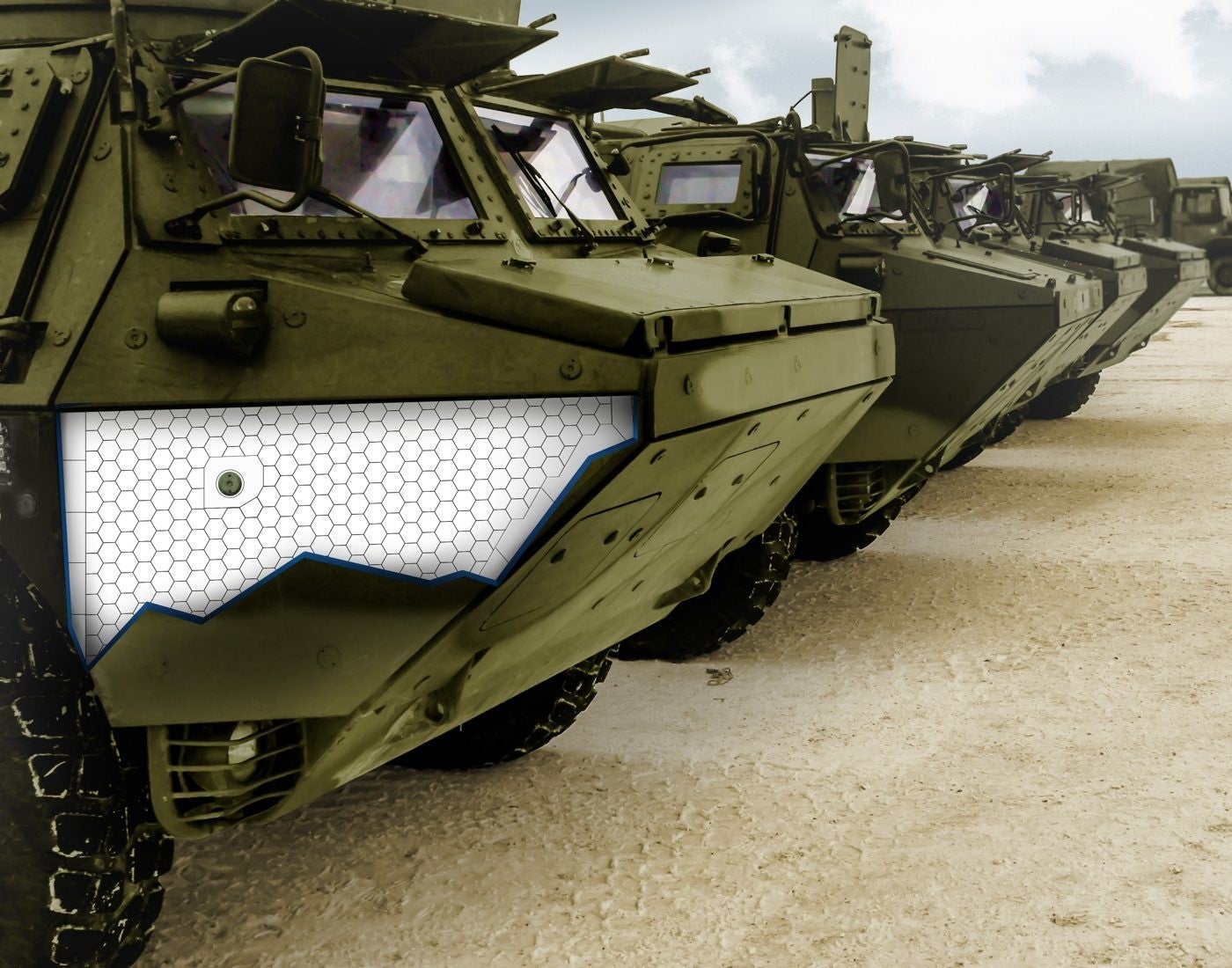

Integrated into armour composite systems, ceramics can reduce the total system weight up to 50% and increase the protection level especially against armour piercing (and kinetic) ammunition, compared with conventional steel armouring solutions. This will influence, for example, the comfort for a soldier or the maneuverability and allowable payload for a vehicle in a very positive way.

High-performance armour ceramics

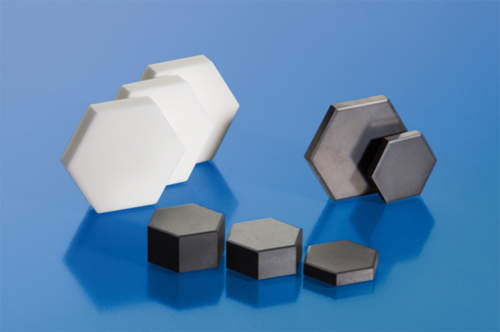

CeramTec-ETEC’s ceramic materials ALOTEC-SB (alumina content of 96% to 99.5%) and SICADUR (silicon carbide) meet all current requirements made towards modern composite armouring systems. Their advantages are a low area weight, high ballistic strength, extremely tight tolerances and universal applicability for aramid, polyethylene and glass-fibre reinforced polymer backings.

Vehicle armour

CeramTec-ETEC has designed and manufactured ceramic panel layouts, both for add-on armour, as well as integrated interior protection systems for more than 20 years. Its ceramic technology has been qualified by numerous national and international armour projects such as German Fox, ASV (M1117), M113, VAB, Dingo, Fennek, LAV Fleet, cabin protection for all kinds of trucks, shelter protection, vessels, VIP and police cars.

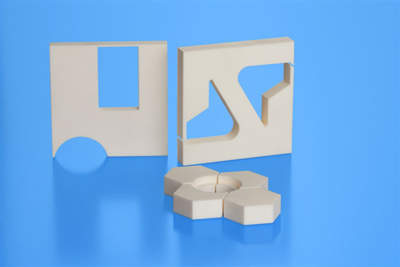

Based on the company’s design and manufacturing expertise developed over many years, CeramTec-ETEC offers customised ceramic panel layouts based on square, hexagonal and engineered tiles in very complex geometries to accommodate customers’ specific requirements. Ceramic components can be supplied as separate tiles or pre-assembled panels, which can be directly put into the production process for the composite assembly.

Body armour

Ceramic single curved multi-tiles plates with various radii of curvature can be supplied as an alternative to monolithic plates to achieve higher multi-hit resistance.

Research and development

CeramTec-ETEC has an excellent team of graduated scientists and experienced technicians to stay at the forefront of ceramic technology.

Together with universities, research institutions such as Fraunhofer, for example, Ernst Mach Institute, and other R&D facilities, the company is working on the development of new materials, manufacturing processes and armour products and testing thereof. This enables us to come up with adequate solutions for future vehicle and body armour requirements.

Quality

A team of highly skilled people, a production plant equipped with the latest machinery, including full CAD engineering and a highly sophisticated quality assurance system certified to ISO 9001: 2008, ensures the production and supply of products with a consistently high-quality.

This enables CeramTec-ETEC to comply with the high standards and tight tolerances required by customers. An intense cooperation with renowned system integrators guarantees a constant quality improvement.