A team of US Army researchers and academic partners from the University of Central Florida (UCL) have optimised the 3D printing process to deliver lightweight components for future soldiers.

The partnership optimised the printing process for the additive manufacturing of a high-strength magnesium alloy called WE43 to enable the delivery of lighter military equipment.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

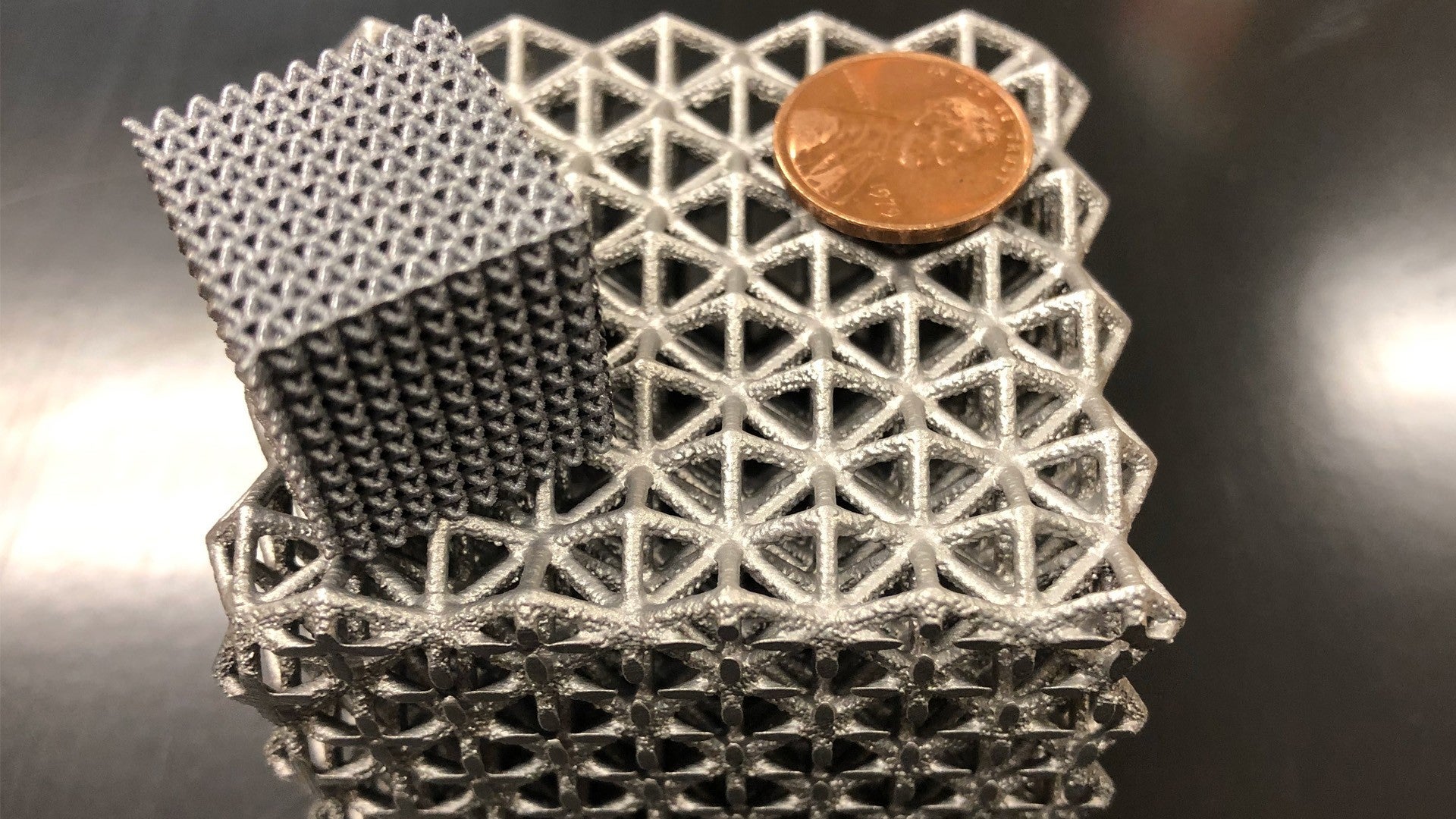

DEVCOM Army Research Laboratory 3D printing metals lead researcher Dr Brandon McWilliams said: “We used a magnesium alloy known as WE43, which has only been successfully 3D printed by a handful of researchers.

“In this work, we optimised the process to achieve higher density than previously reported and used that to produce and characterise lattice structures made up of WE43.”

The findings were published in the peer-reviewed journal Materialia.

The research is aligned with the US Army’s modernisation strategy that seeks to deliver lighter equipment for soldiers.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAdditionally, studies have indicated that advanced additive manufacturing has the potential to deliver critical parts, reducing logistical bottlenecks.

McWilliams added that he expects that combining advanced lightweight alloys with novel multi-scale structures through additive manufacturing will serve as a key aspect of modernising army weapon systems.

McWilliams stated: “Current systems are too heavy, which increases burden to the soldier, reduces fuel efficiency and degrades mission effectiveness.

“It is my goal as an army researcher to conduct research, which has the maximum chance of success of transition from basic and applied research stage to practical application in order to enable transformational overmatch.”

Now, army researchers will assess the high strain rate and ballistic properties of the 3D-printed materials.

In subsequent stages, the team plans to test the material in different applications such as ultra-lightweight unmanned aircraft system and robotic vehicle components.