The Eagle III artillery forward observation vehicle

The Eagle reconnaissance vehicle is manufactured by MOWAG Motorwagenfabrik in Kreuzlingen, Switzerland (owned by General Motors Defense of Canada) and is in service with the armed forces of Denmark and Switzerland.

Eagle I and Eagle II are armoured wheeled reconnaissance vehicles, the slightly heavier Eagle II having a higher power-to-weight ratio than the Eagle I.

The Eagle III is the artillery forward observation vehicle. Eagle IV is the latest production version.

MOWAG is owned by General Motors Defense of Canada, now part of General Dynamics. In November 2003, General Dynamics formed General Dynamics European Land Combat Systems, from MOWAG, Steyr-Daimler-Puch of Austria and General Dynamics, Santa Barbara Sistemas (GDSBS) of Spain.

Eagle deliveries and deployment

The Swiss Army has taken delivery of 156 Eagle I (from 1995) and 175 Eagle II (from 1999). The first of 120 Eagle III vehicles was delivered to the Swiss Army in November 2002. The Danish Army has 36 Eagle I vehicles.

Eagle vehicles were deployed by the Danish Army as part of the United Nations peacekeeping operations in Bosnia and in Albania. The Swiss Eagle vehicles designated are mainly deployed as reconnaissance vehicles for the armoured brigades of the Swiss Army.

Eagle IV foward observation vehicle

In December 2003, GDLS-E Mowag rolled out the Eagle IV 4×4 vehicle. Eagle IV is built on the DURO chassis with payload increased to 2,400kg and a reduction in width of 120mm which allows two fully equipped vehicles to be transported in a C-130 aircraft without special preparation. Eagle IV has increased ballistic weapon and mine protection. It is also available in a non-armoured version.

In December 2005, Denmark ordered 85 Eagle IV vehicles. Deliveries began in September 2006 and were scheduled to conclude by December 2007. The Eagle IV replaces Denmark’s Eagle I.

Eagle IV is equipped with an overhead weapons station. BAE Systems was awarded the contract for the Lemur remotely controlled weapon station for the Danish vehicles in March 2007.

Eagle IV also features a battle management system and ballistic and mine protection for crew and engine compartments, Cummins ISBe 5.9l engine and central tyre inflation system.

In July 2008, the German Army placed an order for 20 Eagle IV vehicles for evaluation. In November 2008, the army ordered 198 Eagle IV vehicles with a further 474 vehicles an option. The first vehicles were delivered and deployed in Afghanistan by May 2009. The remaining deliveries concluded in September 2010. The vehicles are fitted with the KMW FLW100/200 remotely controlled weapon station.

In August 2010, the German Army awarded two additional contracts to General Dynamics for 70 highly protected Eagle IV vehicles. In December 2010, the Bundesamt für Wehrtechnik und Beschaffung (BWB) signed a $165m contract with General Dynamics for the delivery of 195 highly protected EAGLE vehicles. The vehicles are scheduled to be manufactured and delivered in 2011 and 2012.

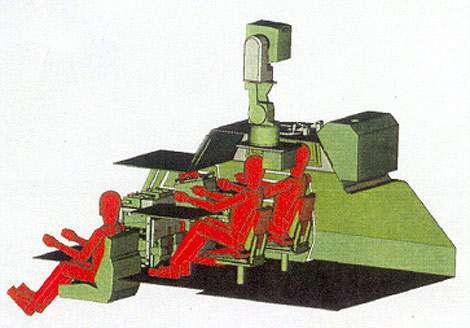

Eagle III artillery forward observation vehicle

The Eagle III is used for target surveillance and acquisition in addition to observation, reconnaissance and patrol missions. Eagle III is operated by a crew of four, the driver and surveyor stationed in the front two seats and the forward observer and signals operator in the cabin.

The vehicle is fitted with a raised roof, panoramic bulletproof windows and an air conditioning system. Eagle III is protected by high-hardness armoured steel and by composite armour. It can also be fitted with mine protection.

The electro-optical target acquisition system combined with a land navigation system is used to provide accurate positional coordinates of a target.

The Rheinmetall Defence Electronics (formerly STN ATLAS Elektronik) BAA observation system is installed on a retractable roof-mounted mast. It comprises a thermal camera with a range of up to 7km, video camera and eyesafe laser rangefinder, both with a range of up to 10km.

Honeywell developed the navigation system with an inertial navigation system and GPS.

For targets at a range up to 7km the target acquisition system provides the positional accuracy of the target to within 50m in the x and y axes and to within 15m in the z axis.

When the target has been acquired and identified, the communications operator transmits the acquisition data using the online radio data transmission link to the integral artillery fire command and control system and to the firing units.

Eagle II reconnaissance vehicle

The reconnaissance vehicle is based on the AM General HMMWV (high-mobility multipurpose wheeled vehicle) chassis. The vehicle is protected with an armoured superstructure developed by Mowag and fitted with a Mowag armoured MBK2 observation cupola. The Eagle is operated by a crew of four – driver, commander, radio operator and observer.

The crew is protected with ballistic armour comprising aluminium plates internally lined with composite armour. Special mine protection enhances the overall level of protection.

The armour increases the width of the vehicle by 100mm compared to the width of the basic HMMWV vehicle and provides protection against 7.62mm and 5.56mm BALL projectiles fired from a range as close as 30m or against 7.62mm steel core projectiles from 100m. The windscreen and windows are bulletproof.

Mowag MBK2 observation cupola

A Mowag MBK2 observation cupola is installed in a central position in the roof. The cupola rotates through 360° and is equipped with a thermal imager providing the capability of all round observation by night and by day, while the crew is fully NBC protected.

A 7.62mm machine gun armed with 400 rounds of ready-to-fire ammunition is installed on the right of the cupola. The gun can be aimed and fired by the crew within the protection of the turret. A bank of six grenade launchers is installed on the rear of the turret. The cupola’s traverse and elevation drives are mechanical.