Researchers at North Carolina State University have demonstrated a new composite metal foam (CMF) material that can stop armour-piercing .50cal rounds from piercing armoured vehicles as effectively as steel, while having the advantage of weighing half as much.

The discovery will allow military vehicles designers to develop much lighter armoured vehicles to the same safety standard as those using conventional steel.

North Carolina State University professor of mechanical and aerospace engineering Afsaneh Rabiei, who invented the material, said: “The CMF armour was less than half the weight of the rolled homogeneous steel armour needed to achieve the same level of protection.

“In other words, we were able to achieve significant weight savings – which benefits vehicle performance and fuel efficiency – without sacrificing protection.”

CMF is a foam made of hollow metallic spheres, usually steel or titanium, embedded within a larger metallic matrix, which can be made from steel, titanium, aluminium or a mix of other metallic alloys. In this instance, the research team used a steel-steel CMF.

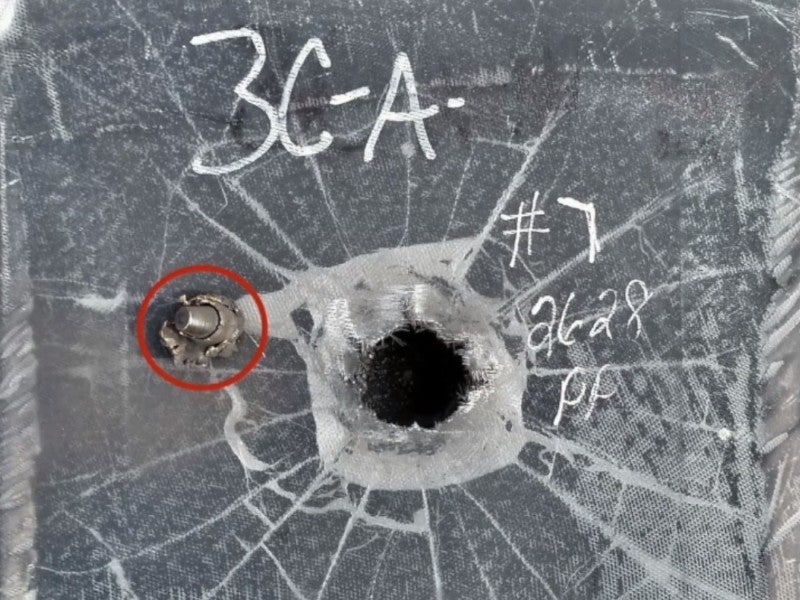

To test the material, the researchers developed a full armour system comprising a ceramic faceplate and a thin aluminium back plate, with the hard CMF sandwiched in between.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe armour was then fired at using .50cal ball and armour-piercing rounds at velocities of between 500m per second and 885m per second. The CMF layer absorbed 72-75% of kinetic energy of the ball rounds and 68-78% of the armour-piercing rounds’ kinetic energy.

“This work shows that CMF can offer a significant advantage for vehicle armour, but there is still room for improvement,” said Rabiei.

“We only optimised our CMF material and replaced the steel plate in standard vehicle armour with steel-steel CMF armour. There is additional work we could do to make it even better. For example, we would like to optimise the adhesion and thickness of the ceramic, CMF and aluminium layers, which may lead to even lower total weight and improved efficiency of the final armour.”

Rabiei and her colleagues have demonstrated the high potential of CMF for armoured vehicles in past experiments, proving it can block blast pressure and fragmentation up to 5,000ft per second from an explosive detonated 18 inches away.

The material has also been proven to be effective in shielding against x-rays, gamma rays and neutron radiation. Furthermore, it can protect against fire and heat twice as effectively as plain metals.

“In short, CMFs hold promise for a variety of applications: from space exploration to shipping nuclear waste, explosives and hazardous materials, to military and security applications and even cars, buses and trains,” she added.