Oxley now offers a wide variety of high-specification filter options to the defence and industrial commercial markets.

The Group has made significant investment in market-leading equipment to produce optical thin film coatings.

Oxley operates an e-beam evaporation box coating system with plasma assisted deposition to ensure excellent coating adhesion in any environment.

Coating takes place in a class 10000 clean room, which also houses state-of-the -art substrate cleaning and filter spectral measurement equipment. Filter dicing and cutting capabilities are also available.

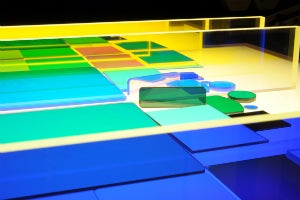

Oxley produces a range of standard filter types but also has the capability to design optical coatings for non-standard requirements.

The standard range of Oxley coated filters are produced on 1mm thick high-quality borofloat substrate and are available in sizes of 25mm diameter and 25mm and 50mm squares. The majority of the following filters are available for the visible or infrared spectral regions.

- Broadband Anti-Reflection Filters: Used to reduce sunlight reflections from screens and displays or to improve the transmission of a window or lens

- Longpass Filters: Act as colour selection filters, contrast enhancement or in conjunction with shortpass filters to produce custom bandpass filters

- Shortpass Filters: Colour selection filters. They contrast enhancement or in conjunction with longpass filters to produce custom bandpass filters

- Bandpass Filters: Used to isolate certain wavelengths or reduce interference from unwanted wavelengths

- Cold Mirrors / Hot Mirrors: Transmit or reflect unwanted infrared (IR) radiation (heat) from a system

- Reflective Neutral Density Filters: Used to reduce spectral output, either broadband or wavelength specific

- Indium Tin Oxide (ITO) windows: For electrical continuity across the surface of a glass filter, as well as electromagnetic compatibility (EMC) protection or heating / demisting.

Oxley engineers are available to assist with the correct selection of filters.