Wisconsin Metal Tech was founded in 1992 by Jeff Heinze and has three distinct product lines, namely CNC machining, centerless grinding and material sales.

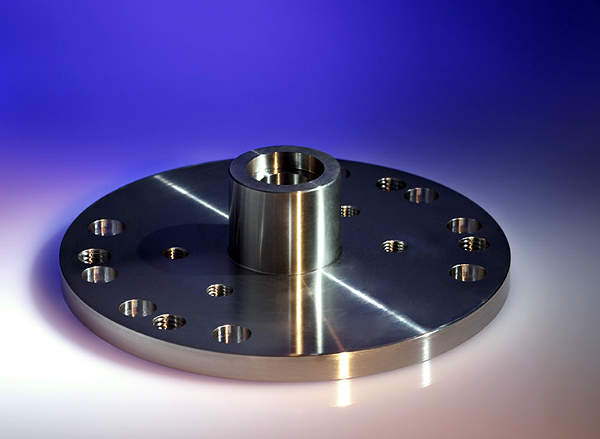

CNC machining for machining simple and complex components

Our CNC division began in the year 2000 when we began to service a longtime customer with CNC machined parts. Outsourcing allowed our customer to concentrate on their core competency, assembly. They wanted to partner with us because of the strong relationship we’d developed during the past ten years.

We can turn utilizing CNC horizontal as well as Swiss lathes. Our lathes are equipped with live tooling and high pressure coolant. We can provide shafts up to 60 inches in length and gun drill to 42 inches. Milling is done on our five axis machining centers.

We have the ability to machine simple as well as very complex parts. You’ll find our niche to be machining of stainless steel.

Centerless grinding for providing ground / polished bars

We took delivery of five centerless grinders in 2001. These complemented the distribution side of the business nicely. They allowed us to provide ground and polished bars, as well as piece part grinding.

We have the capabilities to grind bars, through-feed and infeed grind individual parts. Our capabilities range from 0.06in diameter to 6in diameter.

Tolerances of +/- 0.0001 can be held, along with a four Ra surface finish. Two of our machines have 75hp motors, which allow us to grind larger diameter parts with ease. Our infeed machine is computer-controlled and can compensate in increments of ten-millionths.

Material supply: bars designed to match customer applications

Our niche is providing bars that are custom or unique to a customer’s particular application. We supply bars that have unique features, such as custom diameters, special tolerances, surface finishes, straightness specs or lengths. All of these help minimize material content and cycle times.

Our customer base includes companies that provide metering devices, hydraulic components, food service equipment, conveyors, diesel engine parts and fasteners.

Approximately 80% of our bar sales are to customers who place blanket orders and release as required. We have three cold saws, one band saw and recently added a flaring machine.

Customer service: our key focus

Of all of the services we have to offer, the most important one is customer service. We realize that everyone talks about their excellent service, but this is something that we truly practice every day. It’s not unusual for us to receive, grind and ship finished parts the same day.

We will do whatever it takes to get the job done. This is why our customers keep coming back to Wisconsin Metal Tech, Inc. I encourage you to contact us and see if we can help solve some of your delivery issues.